Πρώτες ύλες εργοστασίου παραγωγής ιχθυάλευρου

Το εργοστάσιο ιχθυάλευρου 24T/D χρησιμοποιεί πέστροφα και τα απόβλητά της ως πρώτη ύλη. Η πέστροφα είναι ένα ψάρι με αρκετά υψηλό ποσοστό λίπους και λαδιού. Κατά την παρασκευή ιχθυάλευρου, μπορούμε επίσης να διαχωρίσουμε το λάδι, ώστε να αποκτήσουμε περισσότερη αξία.

Κατά τη διαδικασία παραγωγής ιχθυάλευρου, πρώτα θρυμματίζουμε την πρώτη ύλη για να την κάνουμε πιο λεπτή και πιο εύκολη στον ατμό. Αυτό το μικρό συμπαγές εργοστάσιο ιχθυάλευρου 5T/24h, όπως υποδηλώνει το όνομά του, μπορεί να επεξεργαστεί 5000 κιλά πρώτης ύλης σε 24 ώρες. Και μπορούμε να πάρουμε περίπου 1000kg-1200kg τελικού ιχθυάλευρου. Η απόδοση ιχθυάλευρου είναι μεταξύ 20% – 25%, και η απόδοση λαδιού είναι μεταξύ 5% – 8% ανάλογα με την πρώτη ύλη.

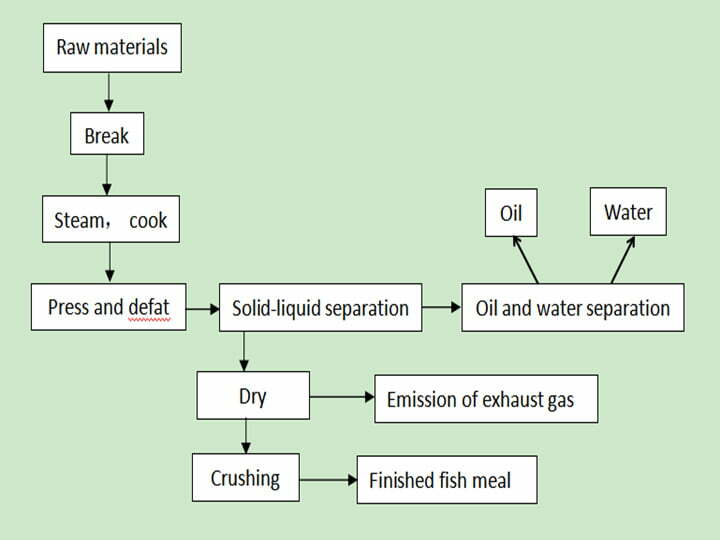

Διαδικασία ροής επεξεργασίας ιχθυάλευρου

- Θρυμματίστε τις πρώτες ύλες με θραυστήρα για να βελτιώσετε το μέγεθος των πρώτων υλών για ατμό.

- Για να διασφαλίσουμε την ποιότητα της επόμενης επεξεργασίας προϊόντων, μπορούμε να χρησιμοποιήσουμε τη μαγειρική μηχανή για να μαγειρέψουμε, να αποστειρώσουμε και να αποστειρώσουμε τα θραυσμένα υλικά σε υψηλή θερμοκρασία.

- Μετά το μαγείρεμα σε υψηλή θερμοκρασία, χρησιμοποιήστε τη μηχανή στύψιμο για να πιέσετε περαιτέρω και να αφαιρέσετε το λίπος από τα μαγειρεμένα υλικά.

- Διαχωρίστε τα πιεσμένα υλικά σε στερεά και υγρά. Στη συνέχεια, το υγρό θα περάσει από τριφασικό φυγόκεντρο για διαχωρισμό λαδιού-νερού, και το νερό και το λάδι μπορούν να ληφθούν.

- Ξήρανση των στερεών και του στερεού σκόνης που λαμβάνονται μετά το πιεστικό, και στη συνέχεια τα θρυμματίζουμε περαιτέρω. Τελικά, μπορούμε να πάρουμε το τελικό ιχθυάλευρο.

- Κατά τη διαδικασία ξήρανσης, μπορεί να παράγεται αέριο εξαγωγής. Χρησιμοποιήστε το cyclone συλλέκτη σκόνης και τον ανεμιστήρα έγχυσης για αποξήρανση και καθαρισμό των αερίων εξαγωγής, και στη συνέχεια απελευθερώστε τα αέρια στον αέρα, ώστε να προστατεύεται το περιβάλλον.

Προδιαγραφή εξοπλισμού παραγωγής ιχθυάλευρου

| Μηχανή ιχθυάλευρου | Κύριος εξοπλισμός και παράμετροι | ΠΟΣΟΤΗΤΑ | Ισχύς (KW) |

Φρέσκος ιχθυοκοπτικός θραυστήρας Φρέσκος ιχθυοκοπτικός θραυστήρας | Προδιαγραφή: μήκος, πλάτος και ύψος (1200X600X1000mm) Ισχύς: Μοτέρ P=5.5kw Το περίβλημα είναι κατασκευασμένο από ανοξείδωτο χάλυβα και το εργαλείο είναι κατασκευασμένο από 40Cr. Χωρητικότητα θραύσης πρώτης ύλης: 500kg-1000kg/h. Το πάνω μέρος είναι εξοπλισμένο με συλλεκτικό κάδο, κατασκευασμένο από ανοξείδωτο ατσάλι SUS304. | 1 | 5.5 |

κοχλιοφόρος μεταφορέας κοχλιοφόρος μεταφορέας | Φ250×4500 Το περίβλημα είναι όλο κατασκευασμένο από SUS304 ανοξείδωτο χάλυβα, δ=3mm, η λεπίδα είναι κατασκευασμένη από SUS304 ανοξείδωτο χάλυβα, δ=4mm; ο άξονας είναι κατασκευασμένος από σωλήνα χωρίς ραφή Φ76X10, υλικό χάλυβας άνθρακα. Διαδρομή: Θραυστήρας-μαγειρική Εξωτερικό μέγεθος: 5.0×0.3×0.3m. | 1 | 2.2 Έλεγχος ταχύτητας μεταβλητής συχνότητας |

| Ψαροκόφτης | Φ426×4000 Ο κύριος άξονας του εξοπλισμού είναι κατασκευασμένος από σωλήνα χωρίς ραφή φ273×10, ο εσωτερικός κύλινδρος είναι κατασκευασμένος από Q345 χάλυβα άνθρακα με πάχος 10mm, το εξωτερικό περίβλημα του εξοπλισμού είναι κατασκευασμένο από Q235 χάλυβα άνθρακα με πάχος 8mm, και η εξωτερική μόνωση είναι από ανοξείδωτο χάλυβα 304 με πάχος 0.7mm. | 1 | 2.2 Έλεγχος ταχύτητας μεταβλητής συχνότητας |

| κοχλιοπρέσα | Φ245×1200 Το σώμα του βαρελιού είναι κατασκευασμένο από διατρημένο σωλήνα χωρίς ραφή, η σπειροειδής λεπίδα είναι πάχους 12mm, και το πλέγμα είναι κατασκευασμένο από ανοξείδωτο χάλυβα 304; το εξωτερικό κάλυμμα και η δεξαμενή λήψης νερού στο κάτω μέρος είναι κατασκευασμένα από ανοξείδωτο χάλυβα 304, πάχους 1.2mm. | 1 | 4 Έλεγχος ταχύτητας μεταβλητής συχνότητας |

| θραυστήρας ιχθυάλευρου | φ820×4000 ο κύριος άξονας του εξοπλισμού υιοθετεί σωλήνα χωρίς ραφή φ273×16, ο εσωτερικός κύλινδρος είναι κατασκευασμένος από Q345 χάλυβα άνθρακα, πάχος 10mm, το εξωτερικό περίβλημα του εξοπλισμού είναι κατασκευασμένο από Q235 χάλυβα άνθρακα, πάχος 8mm, το περίβλημα και ο άξονας και το πηνίο γεμίζονται με ατμό για θέρμανση, η εξωτερική μόνωση είναι από ανοξείδωτο χάλυβα 304, πάχος 0.7mm; V=20 περιστροφές/λεπτό, με περιστροφική σύνδεση και σωλήνα από χάλυβα. | 1 | 7.5 |

| κοχλιοφόρος μεταφορέας συνδεδεμένος με τον στεγνωτήρα | Φ200×4000 Το περίβλημα είναι όλο κατασκευασμένο από SUS304 ανοξείδωτο χάλυβα, δ=3mm, η λεπίδα είναι κατασκευασμένη από SUS304 ανοξείδωτο χάλυβα, δ=4mm; ο άξονας είναι κατασκευασμένος από σωλήνα χωρίς ραφή Φ76X10, υλικό χάλυβας άνθρακα. Εξωτερικό μέγεθος: 4.5×0.3×0.3m. | 1 | 1.5 |

δοχείο καθίζησης λαδιού από ψάρι δοχείο καθίζησης λαδιού από ψάρι | Όγκος 0.5m³ Υλικό: χάλυβας άνθρακα δ=3mm | ||

| Δεξαμενή αποθήκευσης διαχωρισμού λαδιού-νερού | Φ1200×2000 Στατικός διαχωρισμός του υγρού λαδιού και νερού από το ψάρι, βελτιώνοντας την αποτελεσματικότητα και την ποιότητα διαχωρισμού του λαδιού από το ψάρι. Τα μέρη που έρχονται σε επαφή με τα υλικά είναι κατασκευασμένα από Q235B χάλυβα άνθρακα. Ο εξωτερικός μισός σωλήνας γεμίζει με ατμό για να θερμάνει το λάδι και το νερό, επιταχύνοντας το διαχωρισμό λαδιού-νερού. Εξωτερικό μέγεθος: 1.3×1.3×2.5m. Με αντλία γραναζιού 2.2kw. | 1 | 2.2 |

| cyclone συλλέκτης σκόνης | Φ600×1500, δ=2.0mm, υλικό: SUS304 | 1 | |

| ανεμιστήρας με έγχυση από ανοξείδωτο χάλυβα τύπου y6-41 | Φ200×1.2 Εξαεριστικό σωλήνα από ανοξείδωτο χάλυβα 304. Το μήκος του σωλήνα είναι περίπου 12 μέτρα. | 1 | 1.5 |

| Όργανα, βαλβίδες | βαλβίδες διακοπής, πιεσόμετρα, περιστροφικές συνδέσεις, σωλήνες από χάλυβα, κ.λπ. | 1 | |

| ηλεκτρικό πίνακα ελέγχου | συνδέστε τον εξοπλισμό με τα καλώδια και τα καλώδια στο πίνακα ελέγχου Ηλεκτρικά εξαρτήματα υιοθετούν Chint, με αξιόπιστη απόδοση. Ενδείκτης λειτουργίας ηλεκτρικού ελέγχου κουτιού. | 1 |

Βοηθητικός εξοπλισμός

Αν αγοράσετε το συμπαγές εργοστάσιο ιχθυάλευρου 5T/24h, μπορούμε να σας υποστηρίξουμε με ισχύ, βαλβίδα, όργανα, ηλεκτρικό σωλήνα θέρμανσης, όργανο ελέγχου θερμοκρασίας, συσκευή εκκίνησης, θερμαντικό μέσο, θερμοαγώγιμο λάδι 320#, δεξαμενή υψηλής αποθήκευσης λαδιού, δεξαμενή χαμηλής αποθήκευσης λαδιού.

Ο τρόπος μεταφοράς

Μπορούμε να βοηθήσουμε με την αποστολή στη θέση σας.

Τρόπος εγκατάστασης

Αν αγοράσετε τη μηχανή παραγωγής ιχθυάλευρου μας, θα αποστείλουμε εξειδικευμένους τεχνικούς στον τοπικό σας χώρο για να καθοδηγήσουν την εγκατάσταση. Μπορούμε επίσης να εκπαιδεύσουμε τους εργαζόμενους σχετικά με το πώς να λειτουργούν και να διατηρούν τον εξοπλισμό.

Μηχανή επεξεργασίας ιχθυάλευρου 500kg/h τέθηκε σε λειτουργία στη Λιβύη

Ο πελάτης από τη Λιβύη αρχικά σχεδίαζε να παράγει περίπου 10 τόνους ιχθυάλευρου την ημέρα, αλλά επίσης δήλωσε ότι το επενδυτικό του ποσό δεν ήταν υψηλό. Έτσι, προτείναμε ένα εργοστάσιο παραγωγής ιχθυάλευρου 500 kg/h βάσει του προϋπολογισμού του και της πραγματικής κατάστασης του εργοστασίου του. Τελικά, ο πελάτης αποδέχτηκε ευχαρίστως την πρότασή μας.