Balık yemi üretim hattı, balık yemi üretmek için kullanılan bir makinedir ve kedi balığı, sazan, tilapia, süs balığı ve diğer balıklar için yem peletleri üretebilir. Balık yemi üretim ekipmanları arasında tahıl kırıcılar, karıştırıcılar, balık yemi pelet şekillendirme makineleri, kurutucular ve baharat makineleri bulunur. Bu üretim hattının çıkışı 200-300kg/saat'tir. Balık yemi üretimini ve işlenmesini verimli bir şekilde yapabilir.

Balık yemi işleme için hammaddeler

Balık yemi çeşitli tahıllardan yapılır. Balık yemi, mısır, buğday, soya fasulyesi küspesi, sorgum, pirinç gibi tahılların öğütülmesiyle işlenir ve bu tahıllar kullanılarak balık yemi üretilebilir. Ayrıca, belirli oranlarda karıştırıldıktan sonra şekillendirilebilir. Bu sayede, besin değeri daha kapsamlı ve tadı daha çeşitli olur.

Balık yemi hammaddeleri

Balık peletleri

Balık yemi üretim hattı işleme süreci

Hammadde kırma → hammadde hazırlama → karıştırıcı → yem ekstrüderi → kurutma ekipmanı → baharatlama → soğutma konveyörü → paketleme makinesi. İşleme sürecinin bazı özel detayları aşağıda verilmiştir.

Tahıl kırma

Balık yemi pelet makinelerinin üretimi öncelikle malzemelerin kırılması ve toz haline getirilmesiyle başlar. Kırma işlemi sırasında tahılın kırılma derecesi balık yemi üzerinde büyük etki yapar. Genellikle, daha ince öğütüldükçe, kalite artar.

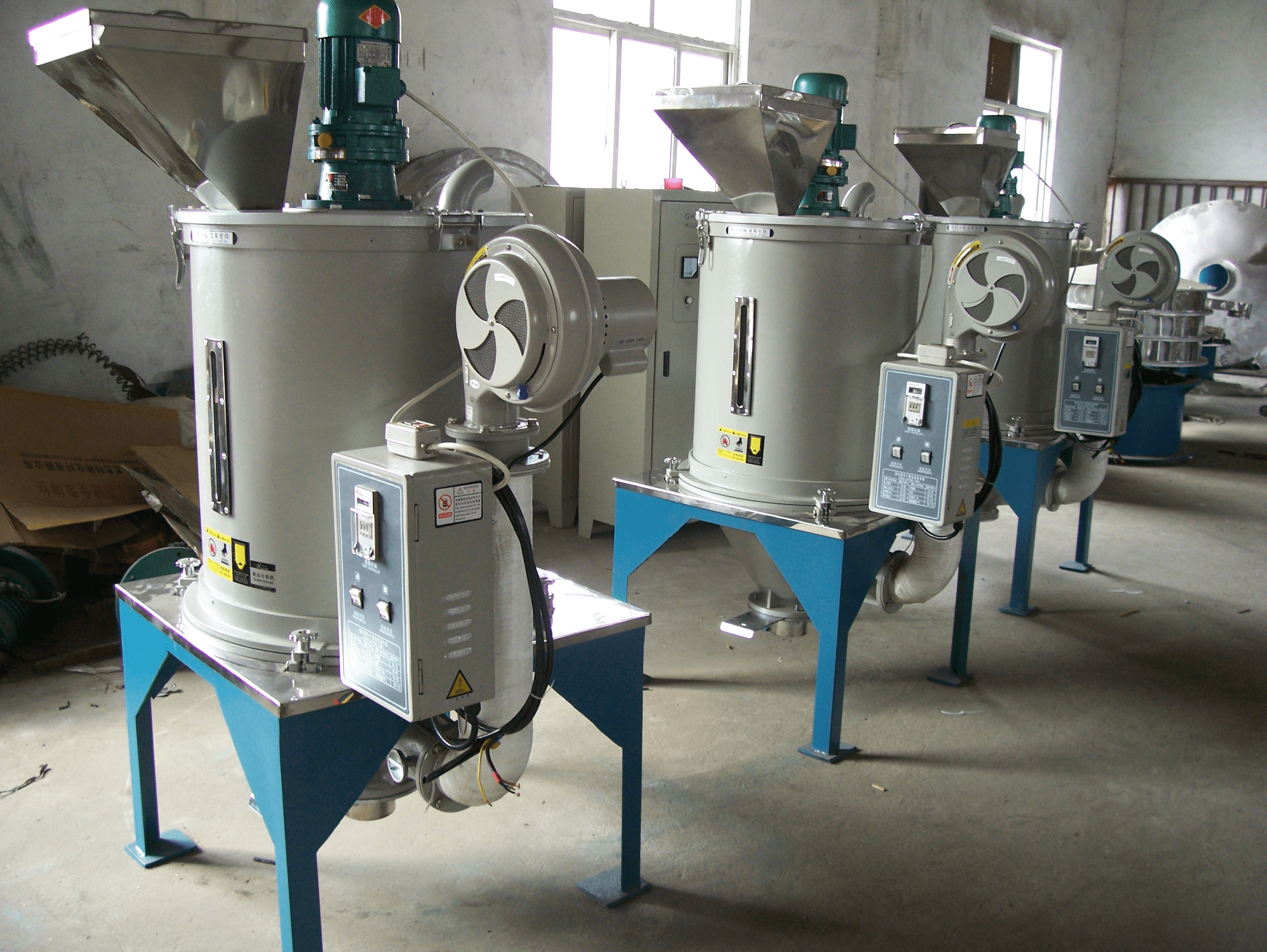

Malzeme karıştırma

Balıkların beslenme açısından kapsamlı olması için, genel balık yemi çeşitli malzemeler içerir. Karıştırmayı eşit yapmak için, karıştırıcı kullanmak gerekir.

Yem şişirme

Karışmış malzemeleri besleme şekillendirme makinesine koyarız ve makine şekillendirir. Balık yemi ekstrüderi ile üretilen yem pişirilir. Salmonella ve diğer bakteriyel mikroorganizmalar yüksek sıcaklıkta öldürülür. Ayrıca, makine farklı şekillerde yemler üretmek için kalıplar kullanabilir ve baharatlandırabilir. Farklı boyuttaki balıklar için, balık yemi peletlerinin boyutları da değişecektir. İşlenmiş balık yemi peletleri şekil ve tat açısından çekici olup, daha lezzetlidir.

Neden balık yemi kurutulmalıdır?

Şişirilmiş balık yemi nispeten yumuşaktır, ancak uzun süreli depolamaya uygun değildir. Kurutucu ile kurutulduktan sonra, balık yemi peletleri raf ömrünü uzatır ve paketleme sonrası taşımaya da uygundur. Kurutma sonrası, balık yemi peletleri su içindeki çözünür vitamin kaybını azaltır ve su kalitesini kirletmez.

| HAYIR. | RESİM |

| 1. kırıcı makine Model:280 Motor:3kw Kapasite:200-300kg/saat |  |

| 2. karıştırıcı makine Model:SL-350 Motor:4kwKapasite:300kg/saat |  |

| 3. Balık pelet makinesi Model: SL-60 Motor:15kw 0.4KW Kapasite:150-200kg/saat Pelet boyut:1.2-12mm |  |

| 4. Balık pelet kurutucu Model: SL-500 Motor:5.5kw Kapasite: 300-400kg/saat |  |

| 5. Aromalandırıcı Tatlandırıcı Karıştırıcı Makine Model 80 değişken hız(1.5KW 380V) Ağırlık 100kg Dönme hızı 27 dev/dak Karıştırma hacmi 0-25 kg/zaman Boyut 1400*1200*1750mm |  |

| 6. paketleme makinesi Model: LFS-1500 Motor: (iki)0.75 0.75 Kapasite:300-500 torba/saat |  |

Şirket Profili

Biz, balıkla ilgili sektörler üreten bir makine şirketiyiz. Diğer ürünler arasında balık unu üretim hatları, tüy unu üretim hatları vb. bulunur. Yurt içi ve yurt dışındaki farklı bölgesel üretim koşullarına göre, 5T, 10T, 20T, 50T, 80T, 100T, 150T, 200T, 300T, 400T, 500T gibi çeşitli taze balık işleme kapasitesine sahip 24 saatlik işleme kapasitesi geliştirilmiştir. Bu, ıslak balık unu üretim hatlarının tam setleri, ıslak balık unu üretim hatlarıdır.