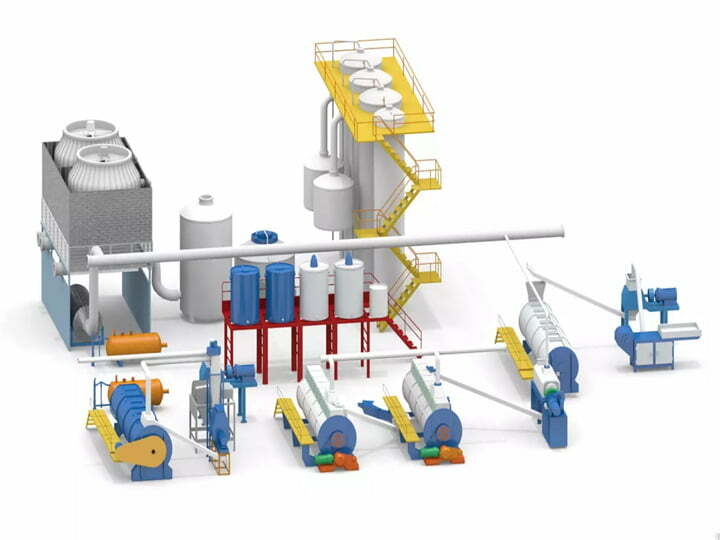

Η Shuli Group είναι μια επαγγελματική επιχείρηση κατασκευής ψαριών, που ενσωματώνει έρευνα, ανάπτυξη, σχεδιασμό και κατασκευή. Μπορούμε όχι μόνο να παρέχουμε γραμμές παραγωγής ψαριών μεγάλης κλίμακας και μικρές ολοκληρωμένες μονάδες, αλλά και να εξοπλίσουμε γραμμές επεξεργασίας ψαριών με διαμορφωμένη παραγωγή σύμφωνα με τις απαιτήσεις του πελάτη. Ο εξοπλισμός εργοστασίου 250T/H σχεδιάζεται σύμφωνα με τις απαιτήσεις του πελάτη. Είναι ένας συνδυασμός 2 γραμμών παραγωγής ψαριών με 125T/12H.

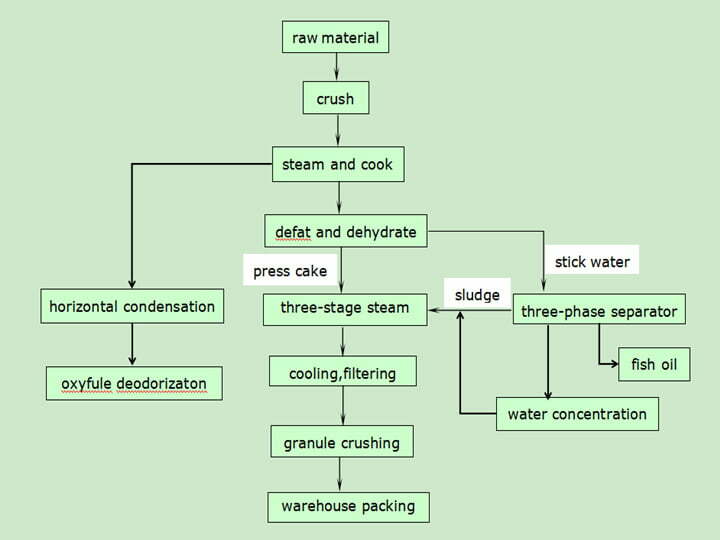

Διαδικασία παραγωγής γραμμής ψαριών

Πρώτα, κόβουμε τα φρέσκα ψάρια με θραυστήρα ψαριών και στη συνέχεια τα βάζουμε στον στεγνωτήρα ψαριών για μαγείρεμα. Κατά τη διαδικασία ξήρανσης, ο συμπυκνωτής δωματίου μπορεί να απομακρύνει τα αέρια. Στη συνέχεια, χρησιμοποιούμε το σπειροειδή πιεστήρα για απομάκρυνση λιπαρών και αφυδάτωση των μαγειρεμένων κομματιών ψαριών, που παράγουν υγρό και πιεσμένο κέικ. Το χυμό μετατρέπεται τελικά σε λάδι ψαριών, ιλύ και πρωτεϊνικό νερό μέσω τριφασικού διαχωριστή. Μετά το στέγνωμα, την ψύξη και το διαλογή, το πιεσμένο κέικ και οι ιλύες γίνονται ψάρι και pellets ψαριών. Επιπλέον, θραύουμε τα pellets ψαριών για να πάρουμε ξανά ψάρι.

Πίνακας αντιστοίχισης εξοπλισμού του εργοστασίου ψαριών 250T/D

Ολόκληρος ο συνδυασμός εξοπλισμού ψαριών περιλαμβάνει εξοπλισμό παραγωγής, μεταφοράς υλικών, διαχωριστήρα λαδιού ψαριών και εξοπλισμό επεξεργασίας αερίων.

Ο εξοπλισμός παραγωγής ψαριών επεξεργάζεται φρέσκα ψάρια σε ψάρι, μέσω θραύσης, μαγειρέματος, στύψιμο, ξήρανση και ψύξη. Ο εξοπλισμός μεταφοράς υλικών μεταφέρει τα υλικά στη γραμμή παραγωγής. Ο εξοπλισμός διαχωρισμού ψαριών διαχωρίζει το λάδι ψαριών, το πρωτεϊνικό νερό και το ψάρι. Ο εξοπλισμός επεξεργασίας αερίων απομακρύνει τα αέρια που παράγονται κατά τη διαδικασία παραγωγής ψαριών, αποτρέποντας τη ρύπανση του αέρα.

Εξοπλισμός παραγωγής ψαριών

| Μηχανή ιχθυάλευρου | Κύριος εξοπλισμός και παράμετροι | ΠΟΣΟΤΗΤΑ | Ισχύς (KW) |

| Θραυστήρας υλικών | Φ600 ● Θραύση φρέσκων ψαριών 9 τόνων ανά ώρα, θραυσμένα σωματίδια ψαριών 30×20mm ●Μέγεθος περιγράμματος: 2.0×1.2×1.7m. | 2 | 22 |

| Μαγειρευτής ψαριών | Φ1000×9000 ●Ο άξονας είναι κατασκευασμένος από Φ730×16 χωρίς ραφή χάλυβα. Ο εσωτερικός και εξωτερικός θερμαντικός κύλινδρος είναι κατασκευασμένος από Q235B χάλυβα, πάχος 12mm, Το πάχος του sandwich είναι 10mm. ●Η λεπίδα θέρμανσης είναι κατασκευασμένη από Q345 με καλή αντοχή στη φθορά, πάχος 6mm. ●Το επάνω κάλυμμα είναι κατασκευασμένο από ανοξείδωτο ατσάλι SUS304. ● Εργασιακή πίεση 0.7MPa, κατανάλωση ατμού 500kg/h ανά μονάδα. ● Με διάσημο περιστροφικό σύνδεσμο και ανοξείδωτο σωλήνα. ●Μέγεθος περιγράμματος: 9.8×1.2×1.4m. | 2 | 7.5 |

| Συρταρωτή πιεστήρα | Φ320X2-1800 ●Χρησιμοποιώντας διπλό σπειροειδή εκτόξευση, με ιδανική πίεση και καλή απομάκρυνση λιπαρών. ●Η λεπίδα του σπειροειδούς είναι κατασκευασμένη από 18mm και 16MnR. ●Ειδικός σχεδιασμός λόγου συμπίεσης σύμφωνα με τα χαρακτηριστικά του πρώτης ύλης ψαριού. ●Ο μειωτής υιοθετεί βαρέως τύπου μονάδα ZQ750-1. ● Το εξωτερικό περίβλημα και η πόρτα του πιεστηρίου είναι κατασκευασμένα από ανοξείδωτο ατσάλι SUS304. ●Μέγεθος περιγράμματος: 4.6×1.0×1.5m. | 2 | 30 |

| Ατμιστήρας στεγνωτήρας | Φ1300×8000 ● Ο θερμαινόμενος χώρος κάθε μονάδας είναι έως 100m2, με ταχεία ξήρανση και υψηλή απόδοση. ● Ο εσωτερικός κύλινδρος του στεγνωτήρα είναι κατασκευασμένος από Q235B με πάχος δ=16mm; ο εξωτερικός κύλινδρος από Q235B με πάχος δ=12mm; η θερμαντική πλάκα είναι 12mm. ●Ο άξονας είναι κατασκευασμένος από Φ377X25 χωρίς ραφή σωλήνα. ●Ο μειωτής είναι κατασκευασμένος από τύπο ZQ750. ●Εργασιακή πίεση 0.7MPa, κατανάλωση ατμού 1000kg/h ανά μονάδα. ●Με διάσημο περιστροφικό σύνδεσμο και ανοξείδωτες σωλήνες. | 4 | 37 |

| Ατμιστήρας στεγνωτήρας | Φ1200×7000 ●Το θερμαινόμενο πεδίο κάθε μονάδας είναι έως 75m2, με ταχεία ξήρανση και υψηλή απόδοση. ●Ο εσωτερικός κύλινδρος του στεγνωτήρα είναι κατασκευασμένος από Q235B με πάχος δ=14mm; ο εξωτερικός κύλινδρος από Q235B με πάχος δ=10mm; η θερμαντική πλάκα είναι 12mm. ●Ο άξονας είναι κατασκευασμένος από Φ377X25 χωρίς ραφή σωλήνα. ●Ο μειωτής είναι κατασκευασμένος από τύπο ZQ650. ●Εργασιακή πίεση 0.7MPa, κατανάλωση ατμού 800kg/h ανά μονάδα. ●Με διάσημο περιστροφικό σύνδεσμο και ανοξείδωτο σωλήνα. ●Μέγεθος περιγράμματος: 7.8×1.6×2.2m. | 2 | 30 |

| Κινητήρας περιστροφής | YF1100*6000 ●Το πλαίσιο είναι κατασκευασμένο από Q235B χάλυβα άνθρακα, και το μέρος που έρχεται σε επαφή με το υλικό είναι κατασκευασμένο από Q235B, δ=8mm. ●ψύξη του υλικού, με δύο επίπεδα αποστράγγισης. ●Ανεμιστήρας έλξης T4-72-3.6A, ισχύς: 3kw. | 2 | 6 |

| ΣΚΣΦ60-40 θραυστήρας | ● Μέγεθος θραύσης σύμφωνα με το εθνικό πρότυπο ψαριού. ●Κατασκευασμένο από T12 εργαλείο χάλυβα, καλή αντοχή στη φθορά. ●Εξοπλισμένο με κυκλωνικό διαχωριστήρα; 7001500 ●Εξοπλισμένο με ανεμιστήρα έλξης; Y6-41-4.5C 5.5kw ● Εξοπλισμένο με ανεμιστήρα διακοπής; 7001500 1.5kw ●Μέγεθος περιγράμματος: 1.5×1.5×1.8m. | 2 | 44 |

Χωρητικότητα δοχείου φιαλών φ800 × 4000 | ●Ο κάδος είναι κατασκευασμένος από Q235B με πάχος πλάκας δ=8mm. ●Ο άξονας είναι κατασκευασμένος από σωλήνα χωρίς ραφή Φ127X25. ●Ο μειωτής είναι κατασκευασμένος από τύπο ZQ500. | 2 | 11 |

| Αυτόματο ζύγισμα και συσκευασία | ● Υλικό: υλικό από ανοξείδωτο ατσάλι 304 σε επαφή με υλικά ● Χωρητικότητα ζύγισης: 2-6 πακέτα/λεπτό ● Φάσμα ζύγισης: 10-50kg/πακέτο ● Σφάλμα ζύγισης: ≤±3‰ ● Μέθοδος ελέγχου: PLC ● Μήκος, πλάτος και ύψος σχήματος: 2650*2080*2450 | 2 | 3.5+1.1 |

Εξοπλισμός μεταφοράς υλικών

| μηχανή ψαριών | προδιαγραφές | Κύριος εξοπλισμός και παράμετροι | ΠΟΣΟΤΗΤΑ | Ισχύς (KW) |

| Ολόκληρο σύνολο εξοπλισμού μεταφοράς | Πρώτες ύλες → μηχανή μαγειρέματος (έλεγχος ταχύτητας με συχνότητα) Φ300×6000 3kw Μηχανή ατμού→μηχανή πιέσεως φ300×5000 3kw Μηχανή πιεσής→πρώτου βαθμού στεγνωτήρας ατμού Φ250×6000 3kw Πρώτος βαθμός στεγνωτήρας ατμού→Δεύτερος βαθμός στεγνωτήρας ατμού Φ250×4500 2.2kw Δευτερεύων στεγνωτήρας ατμού→τριτοβάθμιος στεγνωτήρας ατμού Φ25×4500 2.2kw Τρίτο στάδιο στεγνωτήρας ατμού→ψύξη και διαλογή Φ250×4500 2.2kw Ψύξη και διαλογή→θραυστήρας Φ250×4000 2.2kw Άλεση→αποθήκη Φ250×4000 2.2kw Αποθήκη→συσκευασία Φ250×5000 2.2kw 10.Κεντρί→στεγνωτήρας Φ160×4000 1.5kw | ●Μεταφορά υγρών ψαριών, όλα κατασκευασμένα από ανοξείδωτο ατσάλι SUS304. ●Μεταφορά ξηρών σκόνης, όλα κατασκευασμένα από Q235B χάλυβα άνθρακα. | 20 | 46 |

Εξοπλισμός διαχωρισμού ψαριών

| Μηχανή ιχθυάλευρου | Κύριος εξοπλισμός και παράμετροι | ΠΟΣΟΤΗΤΑ | Ισχύς (KW) |

| Δεξαμενή καθίζησης υγρών ψαριών | ●Μήκος×Πλάτος×Ύψος (2000×3000×2000) | 2 | |

| Τριφασικός διαχωριστής LWS400 | ●Αποτελεσματικός διαχωρισμός υγρών και στερεών ψαριών για βελτίωση της διαχωριστικής απόδοσης και ποιότητας του λαδιού ψαριών. ●Τα μέρη που έρχονται σε επαφή με τα υλικά είναι κατασκευασμένα από ανοξείδωτο ατσάλι. ●Η χωρητικότητα διαχωρισμού είναι 6-10t/h. Ανεξάρτητος κινητήρας μεταβλητής ταχύτητας, εύκολος έλεγχος. ● Διαστάσεις: 3.2×1.1×1.5m. ● Εξοπλισμένο με αντλία υγρών. | 2 | 26 |

| Δεξαμενή αποθήκευσης λαδιού | Φ1000×1800 ●Ο κάδος είναι κατασκευασμένος από Q235B, πάχος πλάκας δ=6mm. ● Πάχος πλάκας sandwich δ=4mm; παραγωγή. ●Συγχρονισμένη αντλία γραναζιών, 1.5kw, κουτί αποθήκευσης | 4 | 1.5 |

Εξοπλισμός επεξεργασίας αερίων

| Μηχανή ιχθυάλευρου | Κύριος εξοπλισμός και παράμετροι | ΠΟΣΟΤΗΤΑ | Ισχύς (KW) |

| Μηχανή συλλογής και συλλογής | Φ800X2000 ● Όλα κατασκευασμένα από ανοξείδωτο ατσάλι SUS304, δ=3mm. | 4 | |

| σωλήνας συμπυκνωτή | Φ800X6000 ●Το σύστημα ψύξης αποτελείται από σωλήνα Φ32×2.0 και SUS304. ●Το περίβλημα είναι κατασκευασμένο από Q235B χάλυβα άνθρακα δ=6mm. | 8 | |

| Απομάκρυνση οξυγόνου με φωτοχημική τεχνολογία | Φ800X6000 ●70 σετ φωτο-οξυγόνων σωλήνων. ●Κέλυφος από SUS304 δ=2mm. ●Χωρητικότητα επεξεργασίας 20000m³. | 2 | 7 |

| Δοχείο ψυχρού νερού NBDL100 | ● Κυκλοφορία θερμού νερού ψύξης, γυάλινο υλικό. ●Χωρητικότητα επεξεργασίας: 100m³/h. ●Διαμόρφωση σωληνώσεων αντλίας 100-100, ισχύς: P=5.5kw 3kw. | 4 | 17 |

| ανεμιστήρας έλξης | Το υλικό είναι κατασκευασμένο από ανοξείδωτο ατσάλι | 2 | 15 |

Άλλος βοηθητικός εξοπλισμός

| Μηχανή ιχθυάλευρου | Κύριος εξοπλισμός και παράμετροι | ΠΟΣΟΤΗΤΑ | Ισχύς (KW) |

| Ηλεκτρικό πίνακα ελέγχου | ●Τα ηλεκτρικά εξαρτήματα είναι κατασκευασμένα από γνωστές κινεζικές μάρκες με αξιόπιστη απόδοση. ●Ηλεκτρικό κουτί ελέγχου με δείκτη λειτουργίας. ●Το ηλεκτρικό κουτί ελέγχου διαθέτει πίσω πόρτα, εύκολη επιθεώρηση και συντήρηση. | 2 | |

| Σύστημα ανάκτησης συμπυκνωμένου ατμού από λέβητα 8 τόνων | εξοικονόμηση ενέργειας περίπου 15% | 2 | 5.5 |

| Υλικά εγκατάστασης, αγωγοί απομάκρυνσης αερίων, σωλήνες, μόνωση, καλώδια, λιπαντικά | 1 |