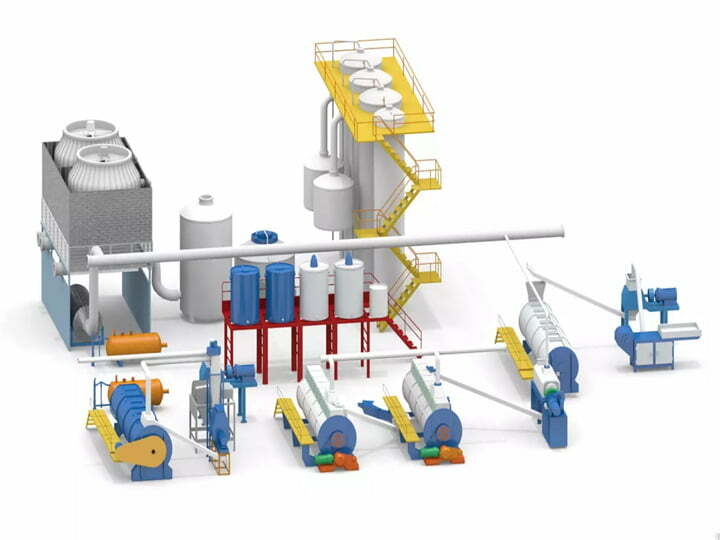

Shuli Group is a professional fishmeal manufacturing enterprise integrating research, development, design, and manufacture. We can not only provide large-scale fish meal production lines and small integrated fish meal plants but also can equip fish meal processing lines with formulated output according to customer’s requirements. The 250T/H fish meal plant equipment is designed according to the customer’s requirements. It is a combination of 2 fish meal plants with 125T/12H.

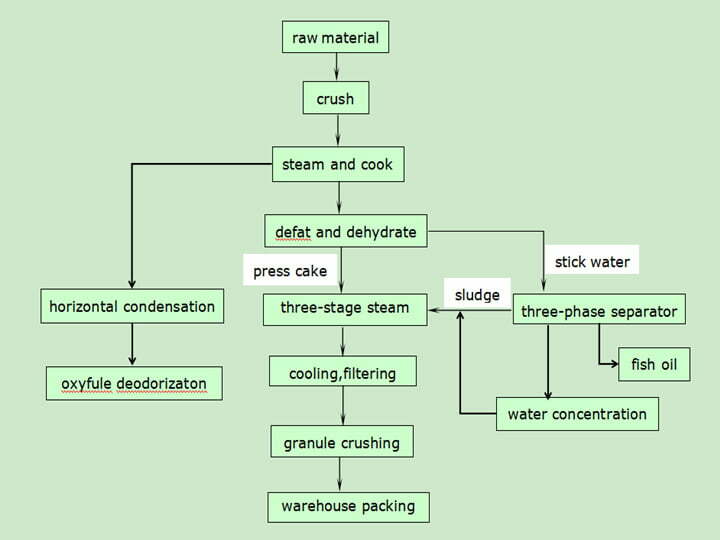

Process flow of fish meal production line

First, cut the fresh raw fish with a fish crusher, and then put it into the fish dryer to cook. In the process of drying, The bedroom condenser can deodorize the exhaust gas. Next, use the screw press to degrease and dehydrate the cooked fish pieces, which can get stick water and press cake. The juice finally turned into fish oil, fish sludge, and protein water through a three-phase separator. After drying cooling, and screening the press cake and sludges, They become fish meal and fish meal pellets. Further, crush the fish meal pellets, and we can get fish meal again. Finally, The fish meal packing machine will pack all the fish produced.

Equipment matching table of 250T/D fish meal plant

यह संपूर्ण मछली आहार संयोजन उपकरण मछली आहार उत्पादन उपकरण, पदार्थ conveying उपकरण, मछली तेल पृथक्करण उपकरण, और निकास गैस उपचार उपकरण शामिल है।

The fish meal production equipment is to process fresh fish into fish meal through crushing, cooking, squeezing, drying and cooling. The material conveying equipment is responsible for the transportation of materials in the production line. Fish oil separation equipment is mainly to separate fish oil, protein water, and fish meal. The exhaust gas treatment equipment is to deodorize the exhaust gas produced in the process of producing fish meal, which can prevent polluting the air.

Fish meal production equipment

| मछली भोजन मशीन | मुख्य उपकरण और पैरामीटर | मात्रा | शक्ति(किलोवाट) |

| Material crusher | Φ600 ● crushing raw fish 9 tons per hour, crushed raw fish crushed particles 30×20mm ●Outline size:2.0×1.2×1.7m. | 2 | 22 |

| Fish cooker | Φ1000×9000 ●The spindle is made of Φ730×16 seamless steel pipe. The inner and outer heating cylinder is made of Q235B steel plate, thickness 12mm, The thickness of the sandwich is 10mm. ●The heating blade is made of Q345 with good wear resistance, thickness 6mm. ●The upper cover is made of stainless steel SUS304. ●Working pressure 0.7MPa, steam consumption 500kg/h per unit. ●With famous brand rotary joint and stainless steel hose. ●Outline size: 9.8×1.2×1.4m. | 2 | 7.5 |

| Screw press | Φ320X2-1800 ●Twin-screw extrusion का उपयोग करते हुए आदर्श प्रेसिंग प्रभाव और अच्छे degreasing प्रभाव के साथ। ●The screw blade is made of 18mm and 16MnR; fish के कच्चे माल की विशेषताओं के अनुसार विशेष संपीड़न अनुपात डिज़ाइन। ●The reducer adopts heavy-duty ZQ750-1 unit. ●The outer casing and door of the press are made of SUS304 stainless steel. ●Outline size:4.6×1.0×1.5m. | 2 | 30 |

| भाप सुखाने वाला | Φ1300×8000 ● The heating area of each unit is up to 100m2, with fast drying speed and high output. ● The inner cylinder of the dryer is made of Q235B with the plate thickness δ inside=16mm; the outer cylinder is made of Q235B with the plate thickness δ outside=12mm; the heating plate is 12mm. ●The spindle is made of Φ377X25 seamless pipe. ●reducer is made of ZQ750 type. ●कार्यात्मक दाब 0.7MPa, प्रति यूनिट भाप खपत 1000kg/h। ●with famous brand rotary joints and stainless steel hoses. | 4 | 37 |

| भाप सुखाने वाला | Φ1200×7000 ●The heating area of each unit is up to 75m2, with fast drying speed and high output. ●The inner cylinder of the dryer is made of Q235B with the plate thickness δ inside=14mm; the outer cylinder is made of Q235B with the plate thickness δ outside=10mm; the heating plate is 12mm. ●The spindle is made of Φ377X25 seamless pipe. ●reducer is made of ZQ650 type. ●Working pressure 0.7MPa, steam consumption 800kg/h per unit. ●प्रसिद्ध ब्रांड रोटरी जॉइंट और स्टेनलेस स्टील होसेज़ के साथ। ●Outline size:7.8×1.6×2.2m. | 2 | 30 |

| रोटरी कूलर | YF1100*6000 ●The bracket is made of Q235B carbon steel, and the part in contact with the material is made of Q235B carbon steel, δ=8mm. ●cooling of the material, with two levels of discharge. ● induced draft fan T4-72-3.6A, power: 3kw. | 2 | 6 |

| SFSP60-40 crusher | ● Crushing size according to national fish meal standard. ●Made of T12 tool steel, good wear resistance. ●Equipped with cyclone separator;7001500 ● Equipped with induced draft fan; Y6-41-4.5C 5.5kw ● Equipped with shut-off fan; 7001500 1.5kw ●Outline size:1.5×1.5×1.8m. | 2 | 44 |

Material bin φ800 × 4000 | ●The barrel is made of Q235B with plate thickness δ=8mm. ●The spindle is made of Φ127X25 seamless pipe. ●The reducer is made of ZQ500 type. | 2 | 11 |

| Automatic weighing and packing machine | ● Material: 304 stainless steel material in contact with materials ● Weighing capacity: 2-6 packs/min ● Weighing range: 10-50kg/package ● Weighing error: ≤±3‰ ● Control method: PLC control ● Shape length, width and height: 2650*2080*2450 | 2 | 3.5+1.1 |

Material conveying equipment

| मछली भोजन मशीन | specifications | मुख्य उपकरण और पैरामीटर | मात्रा | शक्ति(किलोवाट) |

| पूरा सेट conveying उपकरण | Raw material → cooking machine (frequency conversion speed control) Φ300×6000 3kw Steaming machine→pressing machine φ300×5000 3kw Press machine → first-class steam dryer Φ250×6000 3kw First-class steam dryer→Second-class steam dryer Φ250×4500 2.2kw Secondary steam dryer→tertiary steam dryer Φ25×4500 2.2kw Third-stage steam dryer→cooling and screening Φ250×4500 2.2kw Cooling and screening → crusher Φ250×4000 2.2kw Pulverizer → silo Φ250×4000 2.2kw Silo→packaging Φ250×5000 2.2kw 10.Centrifuge→dryer Φ160×4000 1.5kw | ●Conveying wet fish raw materials are all made of SUS304 stainless steel. ●Conveying dry powder materials are all made of Q235B carbon steel. | 20 | 46 |

Fish oil separation equipment

| मछली भोजन मशीन | मुख्य उपकरण और पैरामीटर | मात्रा | शक्ति(किलोवाट) |

| Fish liquid sedimentation tank | ●L×W×H (2000×3000×2000) | 2 | |

| LWS400 Three-phase separator | ●Effective separation of fish liquid solids to improve fish oil separation effect and quality. ●The parts in contact with materials are made of stainless steel. ●The separation capacity is 6-10t/h. Stepless variable speed motor, easy to control. ● Dimension:3.2×1.1×1.5m. ● Equipped with slurry pump. | 2 | 26 |

| Oil storage tank | Φ1000×1800 ●The barrel is made of Q235B, plate thickness δ=6mm. ● sandwich plate thickness δ=4mm; production. ●Matching gear pump,1.5kw, cache box | 4 | 1.5 |

Exhaust gas treatment equipment

| मछली भोजन मशीन | मुख्य उपकरण और पैरामीटर | मात्रा | शक्ति(किलोवाट) |

| Collection and capture machine | Φ800X2000 ● All are made of SUS304 stainless steel,δ=3mm. | 4 | |

| condenser pipe | Φ800X6000 ●The cooling tube is made of Φ32×2.0 and SUS304. ●The shell is made of Q235B carbon steel δ=6mm. | 8 | |

| Photooxygen deodorization | Φ800X6000 ●70 sets of photo-oxygen tubes. ●Shell made of SUS304 δ=2mm. ●Processing capacity 20000m³. | 2 | 7 |

| Coldwater tower NBDL100 | ● Cooling circulating hot water, material glass steel. ●Processing capacity: 100m³/h. ●Configuration of pipeline pump 100-100, power: P=5.5kw 3kw. | 4 | 17 |

| induced draft fan | The material is made of stainless steel | 2 | 15 |

Other auxiliary equipment

| मछली भोजन मशीन | मुख्य उपकरण और पैरामीटर | मात्रा | शक्ति(किलोवाट) |

| विद्युत नियंत्रण कैबिनेट | ● विद्युत घटक चीनी प्रसिद्ध ब्रांडों के बने हैं, जिनका प्रदर्शन विश्वसनीय है। ●Electrical control box with operation indicator. ●The electrical control box adopts a back door, which is convenient for inspection and maintenance. | 2 | |

| 8-ton boiler pressure steam condensate recovery machine system | save energy about 15% | 2 | 5.5 |

| Installation materials, exhaust gas ducts, pipes, insulation, cables, lubricants | 1 |