Birçok endüstri alanında toz toplama ve hava temizliği için, sprey kulesi çok faydalı ve gereklidir. Ayrıca sprey deodorizasyon ekipmanı, sprey arıtma kulesi veya sprey scrubber olarak da adlandırılan bu cihaz, atık gaz arıtma projelerinde maliyet etkin arıtma ekipmanı olarak sıkça kullanılır. Çevreyi korumak amacıyla, her türlü endüstriyel gaz iyi bir şekilde işlenmelidir. Sprey kulesi scrubber, toz ve zararlı gazları birden fazla filtrasyon yoluyla verimli bir şekilde toplayabilir.

Balık unu üretim hattında neden sprey kulesi kullanılır?

Balık unu üretim sürecinde, özellikle balık unu yapım tesisinde veya atölyesinde, çok güçlü ve keskin bir kötü koku olabilir. Balık unu yapımında kullanılan ham maddelerin çoğu ölü veya kokmuş balıklar ve balık başları, kuyrukları gibi balık işleme artıklarıdır ve balık pişirme tankından da kötü koku yayılır. Ayrıca, balık unu kurutulduktan sonra havada çok fazla toz oluşur. Bu nedenle, bu sprey kulesi, balık unu üretim hattında hava arıtımı için çok gerekli bir ekipmandır.

Sprey scrubber nasıl çalışır?

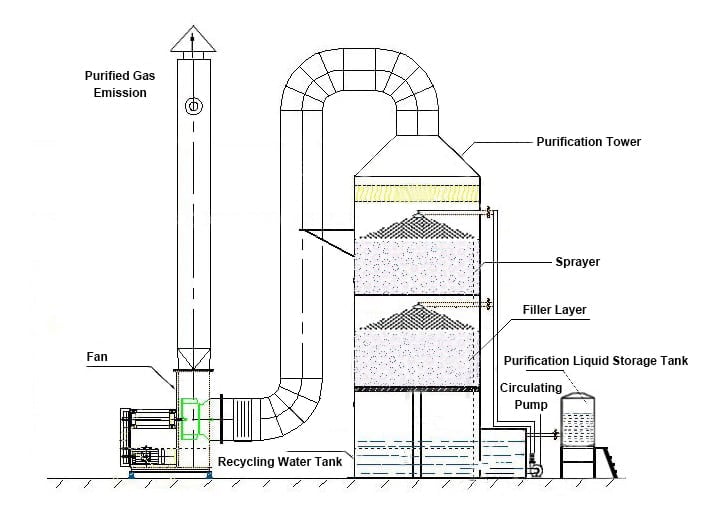

Makine çalışırken, sprey kulesindeki yıkama sıvısı nozul tarafından küçük damlacıklara atomize edilir ve eşit şekilde püskürtülür. Toz gaz, sprey kulesinin alt kısmına girer ve aşağıdan yukarıya doğru akar. İki taraf da karşı akışta temas eder, toz parçacıkları ve su damlacıklarının çarpışmasıyla yoğunlaşır ve yerçekimi etkisiyle çöker. Toplanan toz, sıvı depolama tankına yerçekimiyle çöker ve yüksek katı madde konsantrasyonu içeren sıvı tabakasını oluşturur, bu da periyodik olarak boşaltılır ve daha fazla işlem için kullanılır.

Ayrıca, kısmi arıtma sıvısı, küçük miktarda ek temiz sıvı ile birlikte, dolaşım pompası aracılığıyla nozuldan sprey kulesine püskürtülür. Böylece, yıkama sıvısı tüketimi ve ikincil atık su arıtımı azaltılır. Yıkama sonrası temiz gaz, gaz tarafından taşınan küçük sıvı damlacıklar giderildikten sonra, kulesin üstünden tahliye edilir.

Sprey deodorizasyon ekipmanının temel uygulamaları

Sprey kulesi scrubber, atık gaz arıtma projelerinde yaygın olarak kullanılan maliyet etkin arıtma ekipmanıdır. Sprey deodorizasyon ekipmanı, nitrojen oksitler, hidrojen klorür, hidrojen florür, amonyak gazı, kükürtlü asit sisi, kromik asit sisi ve hidrojen siyanür gazı gibi suda çözünebilir toksik ve zararlı gazları arıtabilir ve amonyak, hidrojen sülfür, fenol, fosgen, formaldehit, metanol ve aminler gibi kötü koku yapan maddelerin deodorize edilmesi ve arıtılması için de uygundur.

Sprey deodorizasyon ekipmanının genellikle iki şekli vardır: dikey sprey kulesi ve yatay sprey kulesi. Sprey deodorizing scrubber, kimya, elektroliz, donanım, alüminyum, elektrikli cihazlar, ilaç, baskı ve boyama, çöp transfer istasyonu, depolama alanı, atık su arıtma tesisi, çiftlik, mezbaha, hastane ve makine işleme gibi endüstrilerde yaygın olarak kullanılabilir.

Dikkat Edilmesi Gerekenler sprey kulesinin kullanımı hakkında

- Kullanım sırasında, emme sıvısındaki asit-baz konsantrasyonu zamanında kontrol edilmelidir. Asit konsantrasyonu çok yüksekse, emme sıvısı zamanında değiştirilmelidir.

- Çevredeki egzoz gazı arıtma ekipmanları temiz ve hijyenik tutulmalıdır.

- Her zaman sprey kulesindeki sprey borusunun tıkanıklığını kontrol edin. Tıkanıklık varsa, zamanında temizlenmeli veya kulesin içi temizlenmelidir.

- Arıtma kulesindeki emme sıvısı, ekleme tankı aracılığıyla eklenir. Eğer fazla emme maddesi kullanıldığını fark edilirse, zamanında eklenmelidir. Emme sıvısı her 8 saatte bir kontrol edilmeli ve eksikse zamanında eklenmelidir.

- Ekipman çalışmayı durdurduğunda, önce 1-2 dakika fanı durdurun, ardından dolaşım suyu pompasını durdurun. Kullanım sırasında, önce dolaşım suyu pompasını 2-3 dakika çalıştırın, ardından fanı açın.

Tüm sprey kulesi parçaları

Toz giderme ve deodorizasyon ekipmanının temel özellikleri

(1) Gelişmiş teknoloji: gelişmiş teknoloji ve gaz fazı kimyasal reaksiyonu kullanılarak, arıtma hızı hızlı ve verim yüksektir.

(2) Düşük enerji tüketimi: Ekipman, düşük hava direnci tasarımı kullanır, bu da fanın gücünü büyük ölçüde tasarruf sağlar.

(3) Düşük işletme maliyeti: rutin bakım için daha az maliyet ve düşük işletme ve bakım maliyetleri.

(4) Yüksek güvenlik: Ekipman ile egzoz gazı arasındaki temas yüksektir ve organik egzoz gazının yanıcı ve patlayıcı özellikleri nedeniyle herhangi bir güvenlik sorunu oluşturmaz.

(5) Güçlü stabilite: Ekipman, uzun süreli çalışmayı sağlamak için tanınmış kartlar kullanılarak yapılmıştır.

(6) Kullanım kolaylığı: İnsan odaklı ekipman tasarımı, yüksek otomasyon seviyesi, kolay bakım.

(7) Dayanıklı: Paslanmaz çelikten yapılmış olup uzun ömürlüdür.