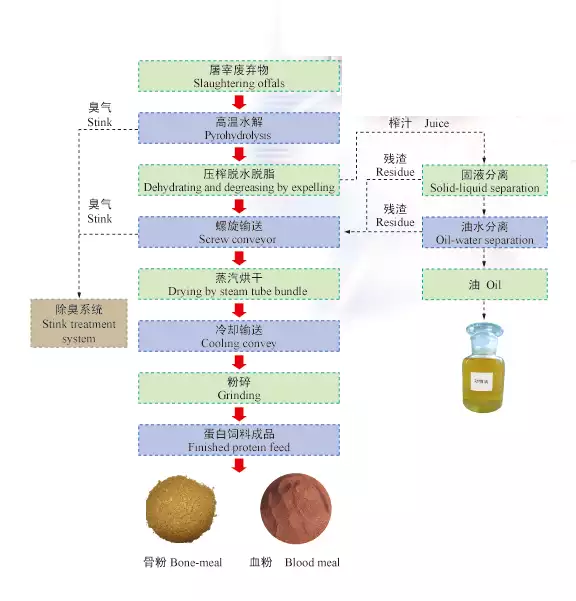

Our meat and bone meal production line uses beef, mutton, poultry, livestock, etc. to process into bone meal and blood meal with a processing scale of 1-5 tons of raw materials per batch. The ratio of meat to bone is about 30% meat, 70% bone. Final products are meat and bone meal and animal fats.

If you want to manufacture bone meal, welcome to contact us for more meat bone meal plant details!

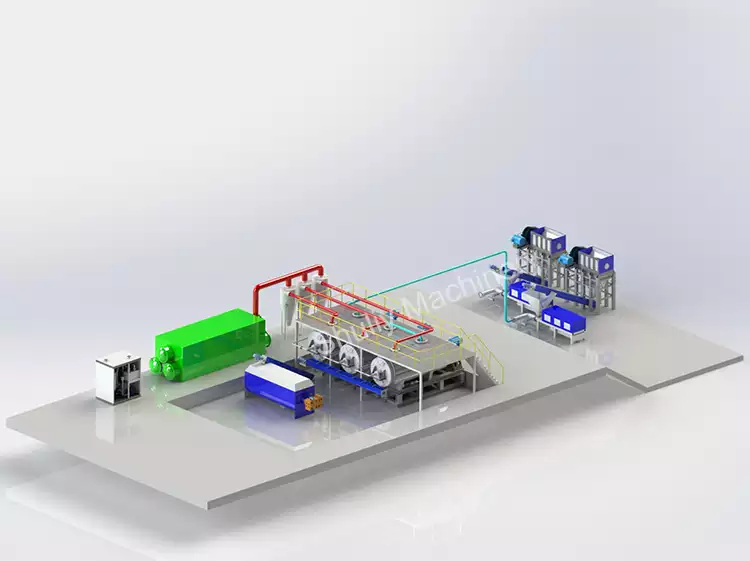

Machine used in meat bone meal (MBM) production line

Based on various practical conditions and economic analysis and comparison, it is planned to use a high-temperature dryer. Other equipment includes a raw material hopper loader, a crusher, a complete set of screw conveyors, presses, and two-phase horizontal dryers. Centrifuge, heating and mixing oil storage tank, rotary cooler, finished product silo, crusher, packaging equipment, waste gas treatment equipment, electrical control part.

How is meat and bone meal produced?

According to the above diagram, you can quickly and easily make bone meal by using slaughtering offals. If you have any questions, come and contact us now!

Unique design of bone meal machine plant

- A complete set of meat and bone meal machine, including the heat source part (including pipes), is insulated with aluminum silicate and rock wool. The thickness of the outer jacket insulation layer of the high-temperature machine is 50mm, which improves the working environment of workers and saves energy.

- All equipment exhaust gas overflow parts in the workshop are drained by negative pressure through pipelines and sent to the exhaust gas treatment system for preliminary condensation and deodorization treatment to improve the working environment.

- During the operation of the meat and bone meal production line, the materials must be transported in an airtight manner so that the finished materials do not fall to the ground and will not cause secondary pollution.

- Motors, reducers, bearings, fans, pumps, valves, instruments, steam traps, rotary joints, wire hoses, and electrical components are all made of China’s first-line famous products, and are selected based on the principles of safety, energy saving, and easy maintenance. Reduce operating costs.

Notes for meat and bone meal production line

- There would be one engineer and one businessman to go for installation and commissioning. The period for installing the bone meal machine would be 20-30 days.

- The complete meat and bone meal production line needs one 2-ton steam boiler. Buyer should prepare the steam boiler before installation.

- The voltage of the bone meal machine plant is 380V, 50HZ.