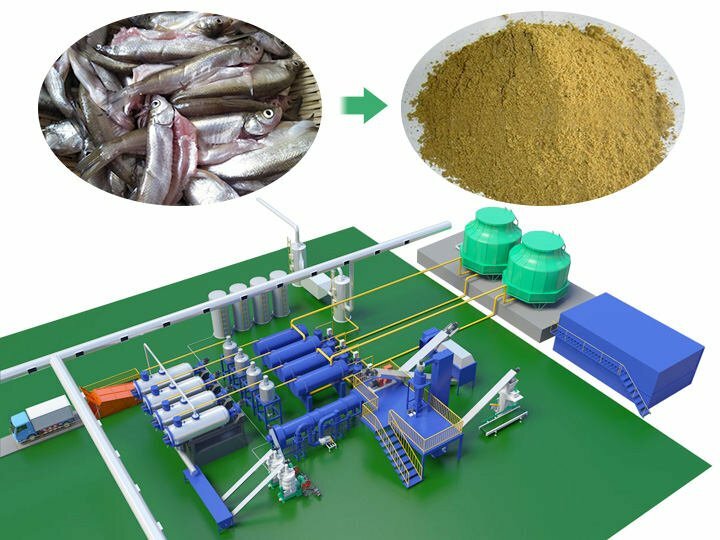

Fish Meal Production Line

September 6, 2019

Fish Crusher | Fish Cutting Machine

September 6, 2019As the leading manufacturer and supplier for fish meal production machinery, we can provide both the whole fishmeal production line for mass production and the integrated type of fish meal production unit for the small or medium yield of the fishmeal making. The onboard fish meal plant is composed of a fish cooking machine, a fish grinding machine, a fishmeal dryer, a separator, a concentrating device, and so on. The fish meal and fish oil production plant can be carried out in small fishmeal production workshops, and can also make fishmeal on the ship while fishing on the sea. Due to the fresh raw fish, it can produce the highest quality fishmeal.

What is the onboard fish meal plant?

Different from the complete type of fish meal production line which is composed of a series of independent fish processing machines, this fish meal plant is an integrated unit for gathering all the functions and crafts of the fishmeal production line. It was designed with a compact and reasonable structure for easy movement and saving space. This fish powder production unit is very suitable for the fish meal making workshop with small and medium yields, besides, this fish meal plant can be set on the ships for making fishmeal and fish oil on the sea.

Advantages of onboard fish meal making machine

- Appropriate price: Compared with large fish meal making equipment , the price of onboard fish meal machine is lower, so customers can achieve considerable additional income with less investment.

- Narrow space : the compact fishmeal plant is integrated with cooking, pressing and drying. It can be installed in the cabin, with strong compactness.

- Strong stability: The onboard fish meal making machine has strong stability, which can effectively solve the problem hull shakes.So,it can ensure the smooth production of fish meal.

Working principle of onboard fish meal plant

In order to process small fish into fish meal,cook the material first.And then,make sure the matured material is pressed and degreased .After that,dry the pressed cake in a steam dryer so that the material is fully dried Under the action of the stirring teeth. After taking the above steps,we get the finished product.

Main parts of the compact fishmeal plant

Although this onboard fish powder making plant is different from the complete fish meal production line, their main fish meal processing crafts are the same. Therefore, we can say this the compact fish meal making unit is a miniature version for making fish powder and fish oil. The main fish processing procedure in this fishmeal production unit includes fish stewing, fish squeezing, and fish meal drying. The customer can choose the fish cutting machine, fish meal crusher, and fishmeal packaging machine, air deodorization system as their supporting equipment for deep processing of their fish meal production based on their actual production requirements.

Working process of the integrated fishmeal making machine

- Use a U-shaped screw conveyor for transporting the fish(with small size) into the fish stewing machine for cooking. If your fish or other animal meat products with big sizes, you should cut them into pieces with the even size of 3-10 cm by an automatic fish cutting machine. If your materials are small fish or mealworms, you can deliver them to the cooking machine directly.

Features:

The outer shell of this conveyor is made of SUS 304 steel with a thickness of 2.5 mm, and its inner screw shaft is made of 3 mm SUS 304 steel.

- Set a boiler for providing the high-temperature steam to stew your raw materials. It can also provide the hot steam for drying the fishmeal in the late fish meal processing stage. The boiler’s steam will enter the fish cooking machine through the pipes and can be recycled for cooking. There are valves, pressure display, and thermometers outside the cooker machine for monitoring all the indicates of fish cooking.

Features:

The cylinder body is made of Φ710×14 seamless steel pipe, and the jacket body is made of Q235B carbon steel material. Equipped with brand name rotary joints and stainless steel hoses.

- The cooked fish pieces will fall into the fish squeezing machine for the separation of the water, fish oil, and the fish slags(wet fish powder). This fish press machine has different working capacities so that the customers can choose a proper one for setting in this fish meal plant. The squeezed liquid of this machine can be further processed by the fish oil production for making fish oil and fish proteins.

Features:

With twin-screw extrusion, the pressing effect is ideal and the degreasing effect is good. The screw blades are made of high quality 14mm 16MnR. The outer casing and door of the press machine are made of SUS304 stainless steel.

- When the fish meal is ground, it needs to be dried by the fishmeal dryer machine because it still has a certain quantity of water content after pressing. The fish powder dryer machine is a drum structure for drying the materials by its continuous rotation. It’s heating resource comes from the high-temperature boiler steam.

Features:

It adopts the coil type (seamless steel pipe Φ76×5) heating method, the thickness of the material for the material is 6mm, and the materials are all made of Q235B carbon steel. The equipment adopts an outer jacket structure with a spacing of mm60mm between the inner and outer layers. Its insulation material is made of aluminum silicate, and the insulation board is made of stainless steel SUS304 with a thickness of 1.0mm.

- Actually, after drying, the fish meal production in this compact fishmeal unit has been finished. However, if you have higher requirements for making fishmeal with the fine powder, you may need to further process the fish meal with a fish meal screening machine and a fishmeal crusher. The fishmeal screening machine mainly can sieve out the big fish meal blocks, and the fish meal crusher will smash them into fine fish powder.

Features:

The fish powder screening machine has both the sieving and cooling functions. Both the screening and crushing machine can match with the dust collector to avoid dust pollution in the working site.

1-2T/D integrated fishmeal making unit

This type of fish meal plant is very suitable for the small fishmeal processing industry, which can make a high-quality fish meal about 1-2 tons per day. It can also be set on the ship for fishmeal making. With the features of space-saving and cost-saving, this integrated fishmeal plant is welcomed in many countries.

Main features of the onboard fishmeal production line

- This fish meal plant is very suitable for the small and medium production of fish powder within 1 ton to 5 tons per day. And you can tell us the fishmeal daily output requirements so that we sill arrange the most suitable type for you, we even can customize your required fishmeal making plant which is based on your actual needs. As for the larger output of fish meal(more than 5 tons a day), we can help you to design the proper fish meal production line.

- For mass production of fishmeal or fish oil, we can provide a series of related equipment for supporting, like the hoist conveyors, stainless steel storage tank, fishmeal quantitative packaging machine, boiler, fish meal crusher, dust collector(cyclone), spray tower, condenser, swing cooler, electric control cabinet, horizontal centrifuge(oil-water separator) and other common spare parts.

Installed example of small fish meal plant

FAQ about fish meal plant

- How much dose a fish meal making machine cost?

A : Different types of equipment correspond to different prices.If you want to buy a fishmeal machine, we will configure the matched parts.And the price of fish meal machines is also related to the quantity and quality of these supporting products.If you want to know the detailed price of the fishmeal equipment, leave your message and we will send you the detailed information.

2 . What is your business model? Trading company or manufacturer?

A : We are a collection of design, research and development, manufacturing, installation as one of the professional machinery production enterprises.We are an experienced manufacturer and exporter for more than 10 years. Our products sell well in Southeast Asia, Africa, South America and other regions.

3 . Do you provide overseas installation service of the fishmeal machine?

A : If you buy our machines , we will dispatch the most professional engineer to your local site to guide the installation. After the installation, the engineers will do the test operation to make sure there is no problem with the machine.

4. Do you provide machine parts?

A : Of course we provide accessories. If you buy the machine from us, we will give you 5% discount on the price of the accessories.