Screw Press | Fish Squeezing Machine

September 9, 2019

Fishmeal Screening Machine

September 9, 2019The fish meal dryer machine is a highly efficient conductive continuous drying equipment for fishmeal processing. This fishmeal drying machine mainly can dry the wet fish powder which is squeezed from the fish squeezing machine and reduce the fishmeal’s water content to less than 10%. After drying, the fish powder can be packed by the automatic fish meal packaging machine. This dryer machine is always used in the fishmeal production line.

Fish meal dryer machine structural features

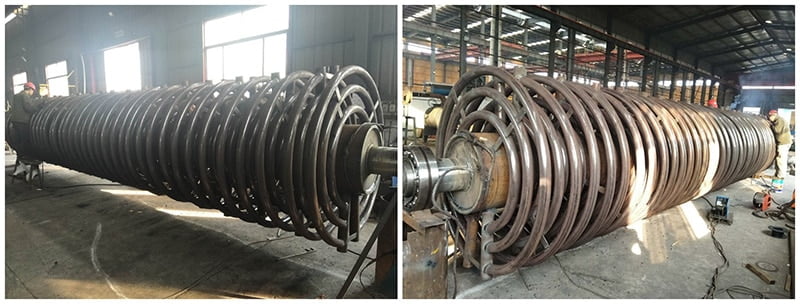

This fish meal dryer machine consists of a recumbent outer casing and a rotating shaft with steam heating. There are many heating coils mounted on the internal shaft. In addition, the heating coil is provided with an adjustable angle scraper. These coils and scrapers work both to heat the material and to move the heated material in the direction of the discharge end.

The steam distribution device inside the shaft allows the steam to be evenly distributed into each of the heating coils in the fishmeal drying machine. The steam continues to flow in the coils on either side of the disc, allowing the heated disc to maintain a constant temperature, while the condensate is discharged through the shaft end swivel.

How does the fishmeal drying machine work?

This fish powder dryer machine heats the material through the heat transfer wall to dry. When the fishmeal is dried, a part of the steam enters the annular space between the outer casing of the machine and the inner wall of the cylinder, and the material is heated through the inner wall. Condensate is drained from the bottom trap.

Another part of the steam enters the main shaft and the coil, and the main shaft and the coil are heated, and the condensed water is discharged from the hydrophobic rotary joint. With the rotation of the rotating shaft, the fishmeal and other materials are fully stirred and mixed under the joint action of the vane and the coil, so that the material has the largest contact with the rotating shaft and the coil surface to ensure the uniform heating and good fishmeal drying effect.

The secondary steam is discharged from the top chamber of the outer casing through the draft duct. There is a weak vacuum condition inside the pipe so that the waste stream does not leak, and it also avoids absorbing too much cold air. The picking plate mounted on the machine’s main shaft is located between the heating coils. It can push the material to move forward and remove the cover layer on the shaft and the cylinder wall to maintain good heat transfer capacity.

Main advantages of the fish meal dryer machine

- This fishmeal dryer machine can match with a dust collector(cyclone) and an induced draft fan for collecting the fish power and avoid dust pollution during the fish meal production site.

- This well-designed dryer machine can make sure that the fishmeal has the largest heating area so that it is evenly heated, and the fish powder drying effect is good, and the drying efficiency is high.

- All parts of this drying machine are made of stainless steel, which improves the corrosion resistance of the machine itself and prolongs its service life.

- The machine is equipped with an automatic water delivery system that recovers steam condensate to the boiler for reuse, reducing energy consumption and saving water.

- This dryer machine can be widely used for drying powdered fish powder, bone powder, dyes, pigments, sludge, chemical products, sawdust, and other powder products.

- fish meal drying machine in use

- fishmeal dryer in fish meal plant