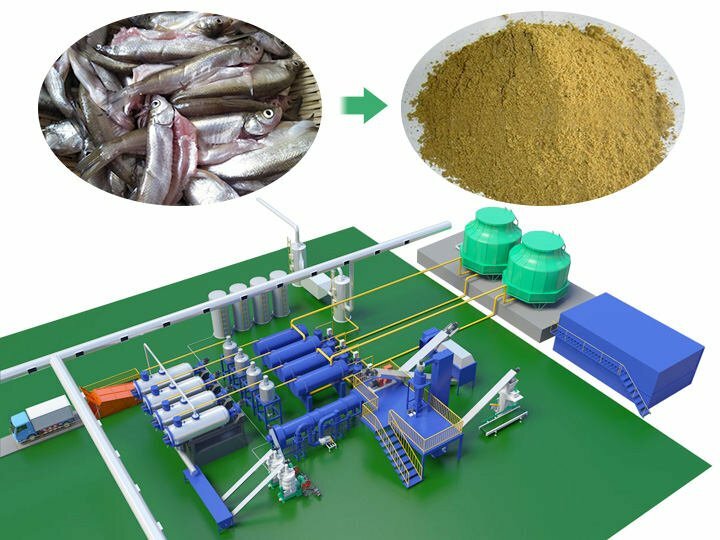

La ligne de production de farine de poisson Shuliy est un ensemble d'équipements spécialisés dans la transformation de déchets de poisson (tels que tête, os, viscères, etc.) ou de poisson frais en farine de poisson riche en protéines et en huile de poisson. Sa capacité varie de 1-5t par jour, 10-50t par jour, 50-100t par jour, 100-250t par jour, et plus.

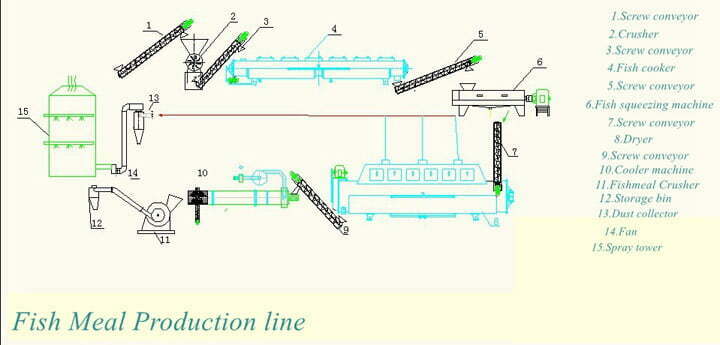

Cette usine de traitement de farine de poisson comprend le broyeur de poisson, le cuiseur à poisson, la presse à vis, le séchoir à vapeur, la machine de refroidissement et de tamisage, la machine à broyer, et la machine d'emballage. Lors de l'étape de la presse à vis, l'huile de poisson est produite. Si vous souhaitez de l'huile de poisson, un séparateur d'huile de poisson est requis.

Il est largement utilisé dans les usines de transformation d'aliments, les fermes aquacoles, les usines de recyclage de protéines animales et autres industries, caractérisé par un rendement élevé et une forte efficacité de protection de l'environnement. Intéressé ? N'hésitez pas à nous contacter pour plus d'informations !

Qu'est-ce que la farine de poisson?

La farine de poisson est une poudre brune riche en protéines et en nutriments, couramment utilisée dans la fabrication d'aliments pour animaux, comme la nourriture pour chats et chiens, la nourriture pour lapins, et l'alimentation avicole. Elle est principalement fabriquée à partir de poissons non destinés à la consommation humaine, de petits poissons, de poissons morts ou de résidus de traitement (par exemple, tête, os, viscères, etc.) après découpe, vapeur, pressage, séchage et autres processus.

En raison de sa haute valeur nutritionnelle et de la demande du marché, la production de farine de poisson est devenue une activité très prometteuse ces dernières années.

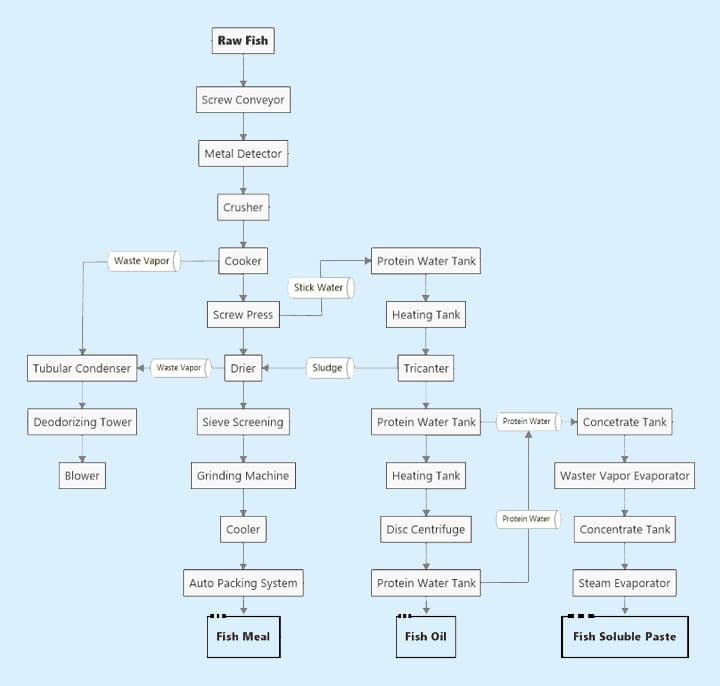

Comment fabriquer de la farine de poisson avec la ligne de production de farine de poisson ?

La procédure courante de traitement de la farine de poisson comprend la coupe du poisson→la cuisson→l'extraction du poisson cuit→le séchage à la vapeur→le refroidissement, le tamisage→la mouture de la farine de poisson→l'emballage de la farine de poisson. Pendant l'extraction, l'huile de poisson est produite. Vérifiez si vous avez besoin d'un séparateur d'huile de poisson.

Étape un : broyage du poisson

Ce broyeur de poisson sert à couper les déchets de poisson, le poisson frais, les crevettes, et les vers de farine, etc., en petits morceaux de ≤5mm. Si vos matières premières sont de petite taille, vous pouvez sauter cette étape en les transportant directement au cuiseur à poisson via le convoyeur à vis.

- Capacité : 500-1000kg/h

- Puissance : 5,5 kW

- Spécification : 1200X600X1000mm (longueur, largeur et hauteur)

- Poids : 300kg

- La coque de la machine est en acier inoxydable et les couteaux en 40Cr.

- La partie supérieure est équipée d'une trémie de collecte, en acier inoxydable SUS304.

Étape deux : cuisson du poisson

La machine à cuire le poisson utilise la méthode de chauffage à vapeur, elle doit donc être associée à une chaudière pour fournir la source de vapeur. La chaudière peut être achetée ou construite par le client lui-même. Cette étape de cuisson du poisson a deux fonctions principales pour la fabrication de farine de poisson : cuisson et stérilisation.

- Temps de cuisson : 20 minutes

- Température de cuisson : 150℃-160℃

- Le cylindre intérieur est en acier au carbone Q345 d'une épaisseur de 10 mm.

- Le cylindre extérieur est en acier Q235 avec une épaisseur de 8 mm.

- Équipé de joints tournants de marque et de tuyaux en acier inoxydable.

- Support monobloc avec garde-corps supplémentaire et échelle d'escalade disponible.

Étape trois : pression du poisson cuit

Les morceaux de poisson cuits sont ensuite transportés dans la machine à presser le poisson pour en extraire rapidement l'eau et la graisse de poisson. Cette machine à vis peut presser au maximum le jus, l'huile de poisson et l'eau du poisson, et évacuer la viande de poisson finement divisée et les résidus de poisson par la sortie de slag.

- Produits finis : farine de poisson brute et humide & mélange eau-huile extraite

- Diamètre de la lame de vis : 18 mm, épaisseur de la lame spiralée : 12 mm, matériau : 16MnR.

- La coque extérieure et le réservoir de réception inférieur sont en acier inoxydable 304.

- Équipement optionnel assorti : séparateur d'huile de poisson

Étape quatre : séchage de la poudre de poisson

Après pressage, les résidus de poisson contiennent encore une certaine quantité d'eau. Par conséquent, nous devons utiliser le séchoir à farine de poisson pour un séchage rapide. Ce séchoir rotatif peut sécher rapidement la farine de poisson lors de sa rotation avec la source de chaleur de la vapeur de chaudière. Ce séchoir est entièrement fermé et équipé d'un collecteur de poussière, ce qui évite la pollution par la poussière.

- Méthode de séchage : séchage à la vapeur

- Le matériau du cylindre extérieur est en acier au carbone Q235, l'épaisseur est adaptée à la capacité de toute la ligne de production de farine de poisson.

- L'équipement est de structure à double enveloppe.

- Le matériau d'isolation thermique est de la silicate d'alumine, et la plaque d'isolation est en acier inoxydable SUS304.

Étape cinq : tamisage et re-broyage de la farine de poisson

Lors de la ligne de production de farine de poisson, après le séchage, la farine doit être tamisée par une machine à tamis à tambour pour obtenir une poudre de poisson de taille uniforme. La machine à tamis à tambour peut être équipée de différents maillages pour différentes tailles de tamis.

- Fonctions : refroidissement et tamisage, déchargement en deux niveaux

- Filet en acier inoxydable, taille : 5mmX5mm

- Le support est en Q235B, et le corps principal est en SUS304, δ=2mm.

Après le tamisage, la poudre fine de poisson peut être emballée, et la poudre de poisson qui n'est pas de la taille requise (généralement 3 mm) peut être broyée à nouveau par une petite machine à broyer avec un collecteur de poussière pour assurer un environnement sans pollution.

- Capacité : 600-800kg/h (9FQ40-28)

- Taille de broyage selon la norme nationale de farine de poisson

- Fabriqué en acier rapide T12 avec une bonne résistance à l'abrasion

Étape six : emballage de la farine de poisson

La farine de poisson finale peut être emballée manuellement ou dans des petits emballages individuels par une machine d'emballage automatique. Nous pouvons fournir une machine d'emballage spéciale pour un conditionnement quantitatif très efficace avec logo, lettres, marques, images personnalisés.

- Modèle : TZ-DGS-50F

- Matériaux d'application : poudre, matériau mélangé

- Capacité de remplissage : 5-50kg

- Précision : ±0,2-0,5%

- Vitesse d'emballage : 3-8 sacs/min

- Consommation d'air/ gaz : 0,4-0,6 MPa / 1 m3/h

- Puissance : 380V/2.6KW

- Dimension : 3000×1500×2500 mm

Principaux avantages de la ligne de production de farine de poisson Shuliy

- Capacités de production variées

- Notre machine à farine de poisson possède une capacité de 1-5 tonnes par jour, 10-50 tonnes par jour, 50-100 tonnes par jour ou plus. Nous pouvons personnaliser différentes lignes de production de farine de poisson en fonction des besoins réels de nos clients.

- Matériaux en acier inoxydable SUS 304 de haute qualité

- Tous les équipements de l'usine de farine de poisson Shuliy adoptent Matériaux en acier inoxydable SUS 304, qui sont résistants à la corrosion et durables. Ainsi, la machine peut être utilisée longtemps.

- Farine de poisson et huile de poisson de haute qualité pour des revenus élevés

- L'utilisation de l'usine de traitement de farine de poisson Shuliy garantit que le La teneur en protéines de la farine de poisson atteint jusqu'à 60% ou plus, contenant une haute teneur en protéines, moins d'impuretés, facile à absorber, et prix de marché plus élevé.

- L'huile de poisson pure extraite peut être utilisée dans le domaine des cosmétiques, pharmaceutiques et des produits de santé, réalisant la valeur maximale des matières premières et augmentant la rentabilité des clients.

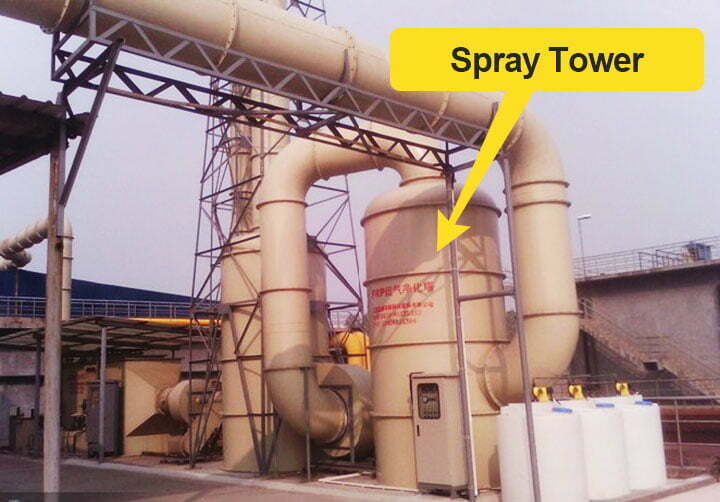

- Programme de traitement de protection de l'environnement

- Nous fournir cyclone (collecteur de poussière), équipement de désodorisation (tour de pulvérisation, condenseur) pour aider les clients à répondre facilement à l'examen environnemental et à respecter les normes d'émission locales.

- Personnalisation et support de service

- Shuliy peut fournir des solutions personnalisées clés en main pour les lignes de production de farine de poisson selon les matières premières, sites, budgets, etc. des clients.

- De plus, nous fournissons l'installation et la mise en service, la formation technique et le service après-vente à distance pour assurer le fonctionnement à long terme et stable de l'équipement.

Applications de la ligne de production de farine de poisson

- Pour fabriquer de l'alimentation pour animaux d'élevage. La farine de poisson peut être utilisée pour la fabrication d'aliments pour certains animaux à fourrure comme les renards et les criquets. Les animaux à fourrure sont principalement carnivores, et la demande en protéines est grande en croissance. La farine de poisson de haute qualité comme matière première protéique est le premier choix pour ces ingrédients d'alimentation animale.

- Alimentation pour animaux aquatiques. La poudre de farine de poisson est utilisée comme matière première principale pour les protéines d'aliments telles que le poisson, les crabes et les crevettes chez les animaux aquatiques. Le ratio d'acides aminés requis pour la farine de poisson et les animaux aquatiques est le plus proche. L'ajout de farine de poisson peut garantir une croissance plus rapide des animaux aquatiques.

- Utilisé pour fabriquer de l'alimentation pour animaux à fourrure. La poudre de poisson peut être utilisée pour fabriquer de l'alimentation pour certains animaux à fourrure comme les renards et les criquets. Les animaux à fourrure sont principalement carnivores, et la demande en protéines est grande en croissance. La farine de poisson de haute qualité comme matière première protéique est le premier choix pour ces ingrédients d'alimentation animale.

Test de fonctionnement de l'usine de farine de poisson

L'usine de farine de poisson peut sécher les matériaux en poudre et granulaires avec des exigences particulières. Pour obtenir de bonnes conditions, une opération d'essai de la machine à farine de poisson est nécessaire.

Les exigences spécifiques sont les suivantes :

- Démarrez le moteur principal et assurez-vous que la direction du rouleau principal est correcte.

- Observez si la rotation du rouleau principal et des composants de transmission est fluide, vérifiez si l'entrée et la sortie de vapeur sont connectées à l'équipement de séchage, et si le manomètre est dans la plage de pression de travail.

- Démarrez le moteur, et le rouleau principal fonctionne en douceur. Après que la température ait augmenté, ajustez la vitesse du moteur et le film uniforme sur le rouleau pour contrôler la teneur en eau du matériau.

- Démarrez le moteur, sortez le matériau sec fini, et ajustez la vitesse du moteur selon la quantité de séchage terminée.

Après avoir terminé les étapes d'essai ci-dessus de l'usine de farine de poisson, s'il n'y a pas de phénomène anormal, vous pouvez commencer à utiliser officiellement.

Équipement associé utilisé dans la ligne de production de farine de poisson

Convoyeur à vis dans l'usine de farine de poisson

Notre usine de traitement de farine de poisson dispose d'un convoyeur à vis spécial, avec une structure simple et un coût faible. C'est un convoyeur couramment utilisé dans l'industrie. Le convoyeur à farine de poisson est fiable, facile à entretenir, et occupe peu d'espace.

Par conséquent, elle peut augmenter l'efficacité de production de la poudre de poisson et économiser beaucoup de coûts de main-d'œuvre.

Dans la production industrielle, il est inévitable de produire des gaz résiduels, de la fumée et de la poussière industrielle. Si ces polluants sont rejetés directement dans l'atmosphère, ils pollueront non seulement l'air mais aussi nuire à la santé des personnes.

Pour éviter les problèmes ci-dessus, nous avons équipé une unité de purification d'air spéciale dans l'usine de farine de poisson, qui est une tour de pulvérisation. La tour de pulvérisation est aussi appelée équipement de désodorisation par pulvérisation, tour de purification par pulvérisation ou épurateur à pulvérisation. Elle peut efficacement collecter la poussière et les gaz nocifs via plusieurs filtres. La performance innovante et avancée de l'équipement de farine de poisson.

L'innovation et la performance avancée de l'usine de farine de poisson

- Nous utilisons l'extraction à air chaud au lieu de la vapeur indirecte d'origine comme source de chaleur sèche, ce qui améliorera considérablement l'efficacité de chauffage. On s'attend à ce que la consommation d'énergie soit réduite de plus de 30 % par rapport à l'équipement de processus d'origine.

- La technologie de séchage rapide à basse température et à court terme peut efficacement protéger les acides aminés de la farine de poisson contre la destruction. Cela réduit le taux de perte de la vraie protéine dans la farine de poisson, passant de 15-30 % à moins de 5 %, atteignant ou dépassant la norme de la farine de poisson.

- Notre conception est maintenue en état de pression négative fermée, avec une production automatique continue, haute efficacité, faible consommation d'énergie, sans pollution pour l'environnement.

Machine à farine de poisson de 500kg/h mise en production en Libye

La farine de poisson a une teneur élevée en protéines et est principalement utilisée dans l'alimentation animale. En raison de sa valeur économique extrêmement élevée, les investisseurs de nombreux pays ont commencé à établir des usines de traitement de farine de poisson pour produire une variété de farine de poisson de haute qualité à grande échelle.

Récemment, un client libyen a passé une commande chez nous. Son usine est située près de la mer et la matière première principale est le poisson blanc.