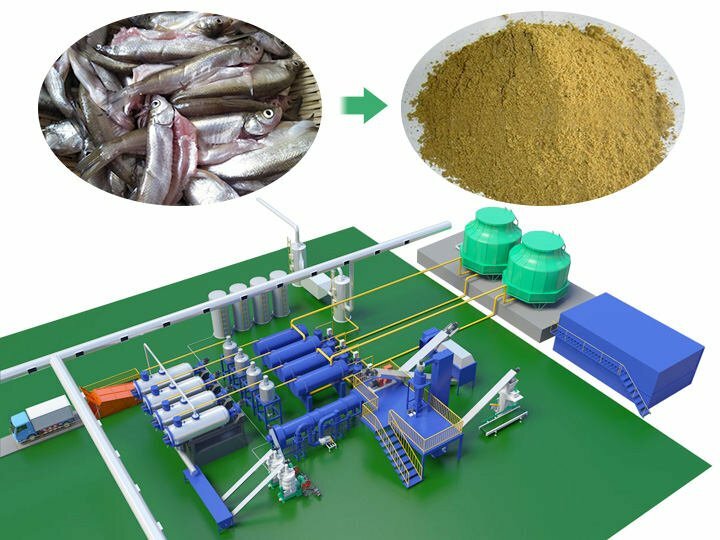

Shuliy barisan pengeluaran ikan ikan adalah satu set peralatan khas untuk menukar sisa ikan (seperti kepala ikan, tulang ikan, isi perut ikan, dsb.) atau ikan segar menjadi ikan ikan berprotein tinggi dan minyak ikan. Kapasiti termasuk 1-5t sehari, 10-50t sehari, 50-100t sehari, 100-250t sehari, dan lebih besar.

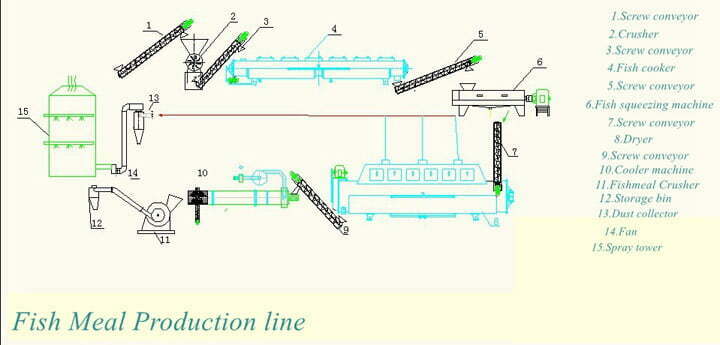

Kilangan ikan ikan ini termasuk penghancur ikan, penjerang ikan, mesin tekan skru, pengering wap, mesin penapis sejuk, mesin pengisar, dan mesin pembungkus. Semasa langkah mesin tekan skru, minyak ikan terhasil. Jika anda nak minyak ikan, diperlukan penapis minyak ikan.

Ia meluas digunakan dalam kilang pemprosesan makanan ternak, ladang akuakultur, kilang kitar semula protein haiwan dan industri lain, dicirikan oleh pulangan pelaburan yang tinggi dan kecekapan perlindungan alam sekitar yang kuat. Berminat? Sila hubungi kami untuk maklumat lanjut!

Apa itu ikan ikan?

Ikan ikan adalah serbuk perang yang kaya protein dan nutrien, yang biasanya digunakan dalam pengeluaran makanan haiwan, seperti makanan kucing dan anjing, makanan arnab, dan makanan unggas. Ia terutamanya diperbuat daripada ikan tertentu yang tidak sesuai untuk kegunaan manusia, ikan kecil, ikan yang mati atau sisa pemprosesan ikan (contohnya kepala ikan, tulang ikan, isi perut, dsb.) selepas pemotongan, pengukusan, pemerah, pengeringan dan proses lain.

Disebabkan nilai pemakanan yang tinggi dan permintaan pasaran, pengeluaran ikan ikan telah menjadi perniagaan yang sangat berpotensi dalam beberapa tahun kebelakangan ini.

Bagaimana membuat ikan ikan dengan barisan pengeluaran ikan ikan?

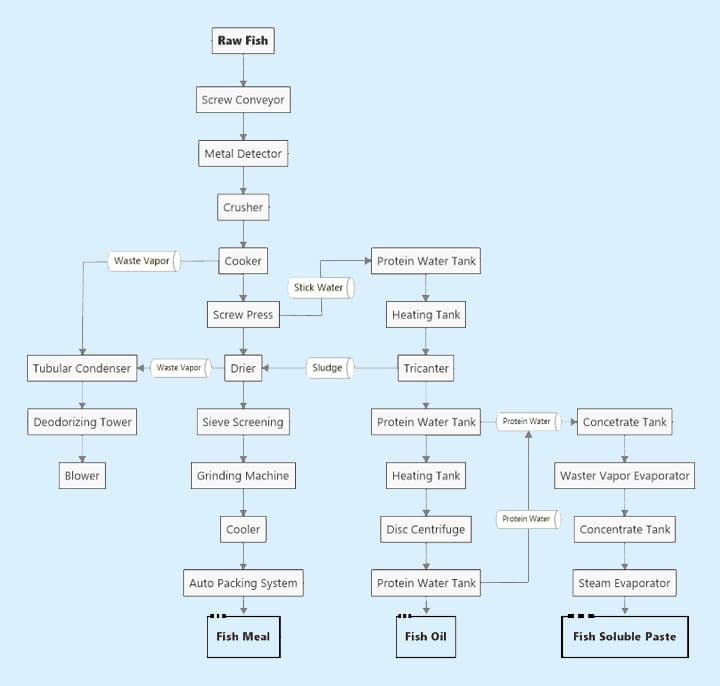

Prosedur pemprosesan ikan yang biasa termasuk memotong ikan→memasak ikan→memerah ikan yang dimasak→pengeringan wap→penyejukan dan penyaringan ikan→penggiling ikan→pek ikan. Semasa proses memerah ikan, minyak ikan terhasil. Lihat jika anda memerlukan penapis minyak ikan.

Langkah satu: menghancurkan ikan

This fish crusher is used to cut fish scraps, fresh fish, shrimp, and mealworms, etc. into small sizes of ≤5mm. If your raw materials are small in size, you can skip this step by transporting them directly to the fish cooker through the screw conveyor.

- Keupayaan: 500-1000kg/j

- Kuasa: 5.5 kW

- Spesifikasi: 1200X600X1000mm(panjang, lebar dan tinggi)

- Berat: 300kg

- Kulit mesin diperbuat daripada keluli tahan karat dan pisau diperbuat daripada 40Cr.

- Bahagian atas dilengkapi dengan pengumpul bereti, diperbuat daripada SUS304.

Langkah dua: memasak ikan

fish cooker machine menggunakan kaedah pemanasan wap, jadi ia perlu dipadankan dengan boiler untuk menyediakan sumber wap. Boiler boleh dibeli atau dibina sendiri oleh pelanggan. Langkah memasak ikan ini mempunyai dua fungsi utama untuk memproses ikan ikan: dimasak dan pensterilan.

- Masa masak: 20 minit

- Suhu masak: 150℃-160℃

- Lkena dalamannya diperbuat daripada keluli karbon Q345 dengan ketebalan 10mm.

- Luar dalaman diperbuat daripada kepingan keluli Q235 dengan ketebalan dinding 8mm.

- Dilengkapi dengan sambungan putar jenama dan hos keluli tahan karat.

- Jentera sokongan satu bahagian dengan langkah perlindungan tambahan dan tangga menaik tersedia.

Langkah tiga: menekan ikan yang dimasak

Potongan ikan yang dimasak akan dibawa ke mesin pengepaman ikan yang seterusnya untuk menekan keluar air dan lemak ikan dengan cepat. Mesin hidraulik skru ini boleh menekan keluar produk jus seperti minyak ikan dan air ikan sehingga maksimum, dan membuang daging ikan halus serta sisa ikan dari outlet buangan slag.

- Produk akhir: ikan ikan kasar dan basah & campuran minyak-air terperhatikan

- Diameter bilah skru ialah 18mm, ketebalan bilah spiral 12mm, bahan 16MnR.

- Lapisan luar dan tangki penerima bawah diperbuat daripada plate keluli tahan karat 304.

- Peralatan sepadan pilihan: penapis minyak ikan

Langkah empat: pengeringan serbuk ikan

Selepas pengeras, sisa ikan masih mempunyai sejumlah kandungan air. Oleh itu, kita perlu menggunakan mesin pengering ikan untuk pengeringan pantas. Mesin pengering berputar ini boleh mengeringkan ikan dengan cepat semasa proses putarannya dengan sumber pemanasan daripada wap boiler. Mesin pengering ini mempunyai struktur tertutup sepenuhnya dan dilengkapi dengan penapis debu, yang tidak menghasilkan pencemaran debu.

- Cara pengeringan: pengeringan wap

- Bahan luar silinder adalah bahan keluli karbon Q235, ketebalan dipadankan dengan kapasiti kilang ikan ikan keseluruhan.

- Peralatan ini mempunyai struktur berkulit luar.

- Bahan penebat terma adalah silikat alumina, dan papan penebat adalah keluli tahan karat SUS304.

Langkah lima: penapisan ikan ikan dan pengegilingan semula

Semasa kilang ikan ikan, selepas pengeringan, ikan ikan perlu disaring oleh mesin penapis drum untuk mendapatkan serbuk ikan yang seragam. Mesin penapis drum boleh ditukar dengan jalur skrin berlainan dengan isip skrin berbeza.

- Fungsi: penyejukan dan penyaringan, dilaksanakan dalam dua peringkat

- Jaring keluli tahan karat, saiz: 5mmX5mm

- Bralang diperbuat daripada bahan Q235B, badan utama diperbuat daripada SUS304, δ=2mm.

Selepas penapisan, serbuk ikan yang halus boleh dibungkus, dan serbuk ikan yang tidak memenuhi saiz yang dikehendaki (biasanya 3 mm) boleh dihancurkan semula oleh mesin penghancur kecil dengan pengumpul debu untuk memastikan persekitaran yang tidak mencemarkan.

- Keupayaan: 600-800kg/j(9FQ40-28)

- Saiz penggilingan mengikut piawaian ikan ikan negara

- Diperbuat daripada keluli aloi alat T12 dengan rintangan kehausan yang baik

Langkah enam: pembungkusan ikan ikan

Ikan ikan akhir boleh dibungkus secara manual atau dibungkus dalam pembungkusan kecil individu oleh mesin pembungkusan automatik. Kita boleh menyediakan mesin pembungkusan khas untuk pembungkusan kuantitatif yang sangat efisien dengan logo, huruf, jenama, gambar yang disesuaikan.

- Model: TZ-DGS-50F

- Bahan permohonan: Serbuk, bahan campuran

- Kisiran pengisian: 5-50kg

- Ketepatan: ±0.2-0.5%

- Kelajuan pembungkusan: 3- 8 beg/minggu

- Tekanan udara/penggunaan gas: 0.4- 0.6MPa/ 1 m3/j

- Kuasa: 380V/2.6KW

- Dimensi: 3000×1500×2500 mm

Kelebihan utama kilang ikan ikan Shuliy

- Pelbagai kapasiti pengeluaran

- Mesin ikan ikan kami mempunyai output 1-5 tan sehari, 10-50 tan sehari, 50-100 tan sehari atau lebih. Kita boleh menyesuaikan barisan pengeluaran ikan ikan berbeza berdasarkan keperluan sebenar pelanggan kami.

- Bahan keluli tahan karat SUS 304 berkualiti

- Semua peralatan dalam kilang ikan ikan Shuliy menggunakan Bahan keluli SUS 304, yang tahan korosi dan tahan lama. Oleh itu, mesin dapat digunakan dalam jangka masa panjang.

- Ikan ikan berkualiti tinggi dan minyak ikan untuk pendapatan tinggi

- Penggunaan kilang pemprosesan ikan ikan Shuliy memastikan bahawa kandungan protein ikan ikan sehingga 60% atau lebih, mengandungi protein tinggi, kekotoran yang lebih sedikit, mudah diserap, dan harga pasaran lebih tinggi.

- Minyak ikan tulen yang diekstrak boleh digunakan dalam bidang kosmetik, farmaseutikal, dan produk penjagaan kesihatan, merealisasikan nilai maksimum bahan mentah dan meningkatkan keuntungan pelanggan.

- Program rawatan perlindungan alam sekitar

- Kami menyediakan cyclone(pencemar debu), peralatan penghilang bau(patung semburan, penyejuk) untuk membantu pelanggan memberi respons kepada ulasan alam sekitar dengan mudah dan mematuhi piawaian pelepasan tempatan.

- Kustomisasi dan sokongan perkhidmatan

- Shuliy boleh sediakan penyelesaian tersuai sehenti untuk garis pengeluaran ikan ikan mengikut bahan mentah pelanggan, tapak, bajet, dsb.

- Selain itu, kami menyediakan pemasangan dan commissioning, latihan teknikal dan perkhidmatan selepas jualan jarak jauh untuk memastikan operasi peralatan yang berpanjangan dan stabil.

Aplikasi kilang ikan ikan

- Untuk membuat makanan ternak. Ikan ikan boleh digunakan untuk pemprosesan makanan haiwan ternak. Ia terutamanya digunakan untuk pengeluaran makanan untuk haiwan seperti babi, ayam, dan lembu. Makanan untuk haiwan ini perlu mengandungi protein berkualiti tinggi, terutamanya untuk anak babi dan ayam. Kerana haiwan muda sedang dalam tempoh pertumbuhan pesat, permintaan protein dan jumlah asid amino dalam protein adalah agak tinggi. Ikan ikan adalah protein haiwan di mana nisbah asid amino paling dekat dengan keperluan asid amino haiwan.

- Makanan untuk haiwan akuatik. Serbuk ikan ikan digunakan sebagai bahan mentah utama untuk protein makanan seperti ikan, ketam, dan udang dalam haiwan akuatik. Nisbah asid amino yang diperlukan untuk ikan ikan dan haiwan akuatik adalah yang paling dekat. Menambah ikan ikan boleh memastikan haiwan akuatik membesar lebih cepat.

- Digunakan untuk membuat makanan untuk haiwan bulu. Serbuk ikan boleh digunakan untuk membuat makanan bagi haiwan bulu seperti musang dan serangga. Haiwan bulu kebanyakannya karnivor, dan permintaan protein adalah tinggi dalam pertumbuhan. Ikan ikan berkualiti tinggi sebagai bahan mentah protein adalah pilihan utama untuk ramuan makanan haiwan ini.

Ujian operasi kilang ikan ikan

Kilangan ikan ikan boleh mengeringkan serbuk dan bahan berbutir dengan keperluan khusus. Untuk mencapai keadaan baik, ujian operasi kilang ikan ikan diperlukan.

Keperluan spesifik adalah seperti berikut:

- Mulakan motor utama dan pastikan stering rol utama betul.

- Pantau sama ada putaran gulung utama dan komponen penghantaran bergerak dengan licin, pantau sama ada inlet dan outlet wap dihubungkan kepada peralatan pengering, dan sama ada tekanan meter berada dalam julat tekanan kerja.

- Mulakan motor, dan gulung utama beroperasi dengan lancar. Selepas suhu naik, laras kelajuan motor dan lipatan seragam pada rol untuk mengawal kandungan air bahan.

- Mula motor, keluarkan bahan kering siap kering, dan sesuaikan kelajuan motor mengikut jumlah pengeringan siap.

Selepas melengkapkan langkah ujian percubaan di kilang ikan ikan di atas, jika tiada fenomena tidak normal, anda boleh memulakan penggunaan rasmi.

Peralatan sepadan yang digunakan dalam kilang ikan ikan

Penghantar skru di kilang ikan herring lama

Kilangan ikan ikan kami mempunyai penghantar skru istimewa, dengan strukturnya yang ringkas dan kos yang rendah. Ia adalah penghantar yang biasa digunakan dalam industri. Penghantar ikan ikan boleh dipercayai, mudah diselenggara, dan mengambil ruang yang kecil.

Oleh itu, ia dapat meningkatkan kecekapan pengeluaran serbuk ikan dan menjimatkan banyak kos tenaga kerja.

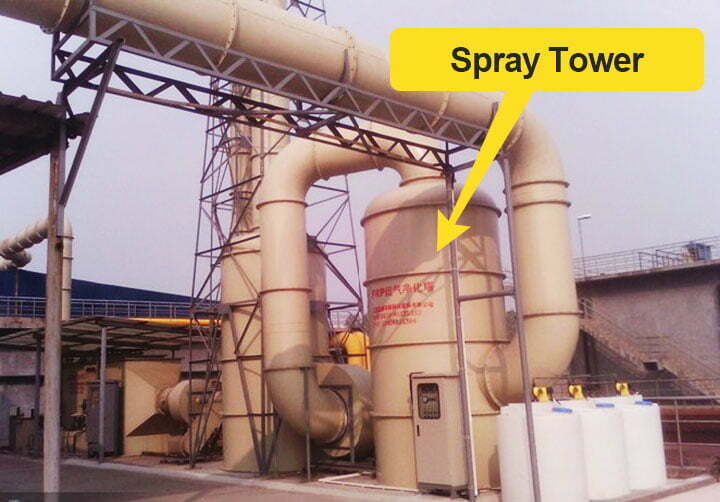

Dalam pengeluaran industri, tidak dapat dielakkan untuk menghasilkan beberapa gas buangan, asap dan debu industri. Jika pencemar ini dibuang terus ke atmosfera, ia tidak hanya akan mencemarkan udara tetapi juga membahayakan kesihatan manusia.

Untuk mengelakkan masalah di atas, kami dilengkapi unit penulenan udara khas dalam kilang pemprosesan ikan ikan, iaitu menara sembur. Menara sembur juga dikenali sebagai peralatan penyingkiran bau semburan, menara penyucian semburan atau scrubber semburan. Ia boleh mengumpulkan debu dan gas berbahaya melalui beberapa penapis. Prestasi inovatif dan maju peralatan ikan ikan

Inovasi dan prestasi maju kilang ikan ikan

- Kami menggunakan pengambilan udara panas dan bukannya wap tidak langsung sebagai sumber haba kering, dan kecekapan pemanasan akan meningkat dengan ketara. Dijangkakan penggunaan tenaga akan menjimatkan lebih dari 30% berbanding peralatan proses asal.

- Teknologi pengeringan pantas suhu rendah boleh melindungi asid amino dalam ikan ikan daripada terjejas dengan berkesan. Ini mengurangkan kadar kehilangan protein sebenar dalam ikan ikan daripada 15-30% kepada kurang daripada 5%, mencapai atau melebihi piawaian ikan ikan yang sama.

- Reka bentuk kami dikekalkan dalam keadaan tekanan negatif tertutup, dengan pengeluaran automatik berterusan, kecekapan tinggi, penggunaan tenaga rendah, tiada pencemaran kepada persekitaran.

Mesin ikan ikan 500kg/j dimulakan di Libya

Ikan ikan mempunyai kandungan protein yang tinggi dan terutamanya digunakan dalam makanan haiwan. Disebabkan nilai ekonominya yang sangat tinggi, pelabur di banyak negara telah mula menubuhkan kilang pemprosesan ikan ikan untuk menghasilkan pelbagai ikan ikan berkualiti tinggi secara besar-besaran.

Baru-baru ini, seorang pelanggan Libya telah membuat pesanan dengan kami. Kilangnya terletak di tepi laut dan bahan mentah utamanya ialah ikan putih.