A linha de produção de farinha de peixe da Shuliy é um conjunto de equipamentos especializado na conversão de resíduos de peixe (como cabeça, espinha, vísceras, etc.) ou peixe fresco em farinha de peixe de alta proteína e óleo de peixe. Sua capacidade varia de 1-5t por dia, 10-50t por dia, 50-100t por dia, 100-250t por dia, e até maior.

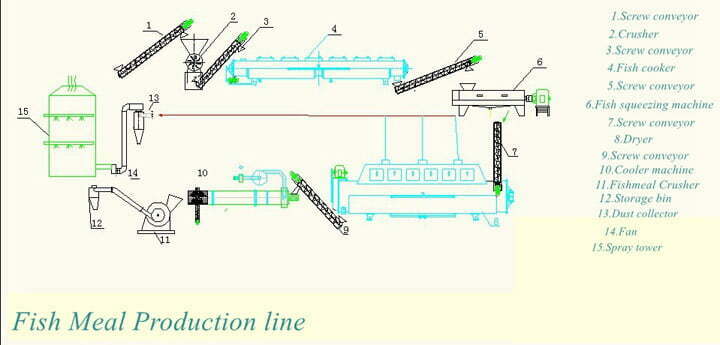

Esta planta de processamento de farinha de peixe inclui o triturador de peixe, cozedor de peixe, prensa de parafuso, secador a vapor, máquina de triagem de resfriamento, moinho e máquina de embalagem. Durante a etapa de prensagem, é produzido o óleo de peixe. Se desejar óleo de peixe, é necessário um separador de óleo de peixe.

É amplamente utilizado em fábricas de ração, fazendas de aquicultura, plantas de reciclagem de proteína animal e outros setores, caracterizando-se por alto retorno de investimento e forte eficiência de proteção ambiental. Interessado? Entre em contato conosco para mais informações!

O que é farinha de peixe?

A farinha de peixe é um pó marrom rico em proteínas e nutrientes, comumente usado na produção de rações animais, como ração para gatos e cães, ração para coelhos e aves. É principalmente feita de alguns peixes que não são adequados para consumo humano, peixes pequenos, peixes mortos ou resíduos de processamento de peixe (por exemplo, cabeça, espinhas, vísceras, etc.) após corte, vapor, prensagem, secagem e outros processos.

Devido ao alto valor nutricional e à demanda de mercado, a produção de farinha de peixe tornou-se um negócio muito promissor nos últimos anos.

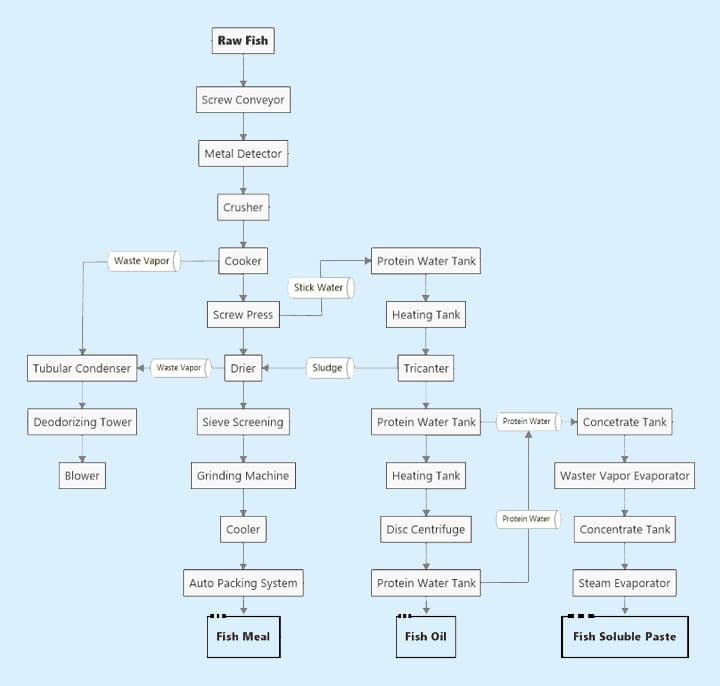

Como fazer farinha de peixe com a linha de produção de farinha de peixe?

O procedimento comum de processamento de farinha de peixe inclui corte de peixe→cozimento do peixe→prensagem do peixe cozido→secagem a vapor→resfriamento e triagem da farinha de peixe→moagem da farinha de peixe→embalagem da farinha de peixe. Durante a prensagem do peixe, é produzido o óleo de peixe. Veja se você precisa de um separador de óleo de peixe.

Primeiro passo: trituração do peixe

Esta máquina de esmagamento de peixe é usada para cortar resíduos de peixe, peixe fresco, camarão e tenébrios, etc., em tamanhos pequenos de ≤5mm. Se suas matérias-primas forem de tamanho pequeno, você pode pular esta etapa transportando-as diretamente para a máquina de cozimento de peixe através do alimentador de parafuso.

- Capacidade: 500-1000kg/h

- Potência: 5,5 kW

- Especificação: 1200X600X1000mm (comprimento, largura e altura)

- Peso: 300kg

- A carcaça da máquina é feita de aço inoxidável e as lâminas são feitas de 40Cr.

- A parte superior é equipada com um funil coletor, feito de aço inox SUS304.

Segundo passo: cozimento do peixe

A máquina de cozimento de peixe adota o método de aquecimento a vapor, portanto deve ser combinada com uma caldeira para fornecer a fonte de vapor. A caldeira pode ser adquirida ou construída pelos próprios clientes. Esta etapa de cozimento do peixe tem duas funções principais para o processamento de farinha de peixe: cozimento e esterilização.

- Tempo de cozimento: 20 minutos

- Temperatura de cozimento: 150℃-160℃

- O cilindro interno é feito de aço carbono Q345 com espessura de 10mm.

- O cilindro externo é feito de chapa de aço Q235 com espessura de 8mm.

- Equipado com juntas giratórias de marca e mangueiras de aço inox.

- Suporte de peça única com guarda-corpo adicional e escada de acesso.

Terceiro passo: prensagem do peixe cozido

Os pedaços de peixe cozidos são então transportados para a máquina de prensagem de peixe para extrair rapidamente a água e a gordura do peixe. Esta máquina de prensa de parafuso pode extrair ao máximo os produtos de suco, como óleo de peixe e água, e descarregar a carne de peixe finamente dividida e resíduos na saída de descarte de escória.

- Produtos finais: farinha de peixe crua e úmida & mistura de óleo e água extraída

- Diâmetro da lâmina de parafuso de 18mm, espessura da lâmina espiral de 12mm, material 16MnR.

- A cobertura externa e o tanque de recepção inferior são feitos de chapa de aço inox 304.

- Equipamento opcional compatível: separador de óleo de peixe

Quarta etapa: secagem do pó de peixe

Após a prensagem, os resíduos de peixe ainda contêm uma certa quantidade de água. Portanto, devemos usar a máquina de secagem de farinha de peixe para secagem rápida. Esta máquina de secagem rotativa pode secar rapidamente a farinha de peixe durante seu processo de rotação com a fonte de calor de vapor de caldeira. Esta máquina de secagem possui estrutura totalmente fechada e está equipada com um coletor de poeira, que não produzirá poluição por poeira.

- Método de secagem: secagem a vapor

- O material do cilindro externo é aço carbono Q235, com espessura compatível com a capacidade de toda a linha de produção de farinha de peixe.

- O equipamento possui estrutura de jaqueta externa.

- O material de isolamento térmico é silicato de alumina, e a placa de isolamento é de aço inox SUS304.

Quinta etapa: triagem e re-trituração da farinha de peixe

Durante a linha de produção de farinha de peixe, após a secagem, a farinha de peixe deve ser peneirada por uma máquina de triagem de tambor para obter farinha de tamanho uniforme. A máquina de triagem de tambor pode ser trocada com diferentes telas de peneira com diferentes furos de triagem.

- Funções: resfriamento e triagem, descarregadas em dois níveis

- Tela de aço inoxidável, tamanho: 5mmX5mm

- O suporte é feito de Q235B, e o corpo principal é feito de SUS304, δ=2mm.

Após a triagem, a farinha de peixe fina pode ser embalada, e a farinha de peixe que não possui o tamanho requerido (geralmente 3 mm) pode ser triturada novamente por uma pequena máquina de triturador com coletor de poeira para garantir um ambiente sem poluição.

- Capacidade: 600-800kg/h(9FQ40-28)

- Tamanho de moagem de acordo com o padrão nacional de farinha de peixe

- Feito de aço ferramenta T12 com boa resistência ao desgaste

Sexta etapa: embalagem de farinha de peixe

A farinha de peixe final pode ser embalada manualmente ou embalada em pequenas embalagens por uma máquina de embalagem automática. Podemos fornecer uma máquina de embalagem especial para embalagem quantitativa altamente eficiente de produtos de farinha de peixe com logotipo, letras, marcas, imagens personalizadas, etc.

- Modelo: TZ-DGS-50F

- Materiais de aplicação: pó, material misto

- Faixa de enchimento: 5-50kg

- Precisão: ±0,2-0,5%

- Velocidade de embalagem: 3-8 sacos/min

- Pressão de ar/consumo de gás: 0,4-0,6MPa/1 m3/h

- Potência: 380V/2,6KW

- Dimensão: 3000×1500×2500 mm

Principais vantagens da linha de produção de farinha de peixe da Shuliy

- Capacidades de produção variadas

- Nossa máquina de farinha de peixe possui uma produção de 1-5 toneladas por dia, 10-50 toneladas por dia, 50-100 toneladas por dia ou mais. Podemos personalizar diferentes linhas de produção de farinha de peixe com base nas necessidades reais de nossos clientes.

- Materiais de aço inox SUS 304 de alta qualidade

- Todos os equipamentos na planta de farinha de peixe da Shuliy adotam Materiais de aço inox SUS 304, que são resistentes à corrosão e duráveis. Assim, a máquina pode ser usada por um longo período.

- Farinha de peixe e óleo de peixe de alta qualidade para alta receita

- O uso da planta de processamento de farinha de peixe Shuliy garante que o o teor de proteína da farinha de peixe chega a 60% ou mais, contendo alta proteína, menos impurezas, fácil de absorver e com preço de mercado mais alto.

- O óleo de peixe puro extraído pode ser usado nos setores de cosméticos, farmacêuticos e produtos de saúde, realizando o máximo valor dos materiais brutos e aumentando a lucratividade dos clientes.

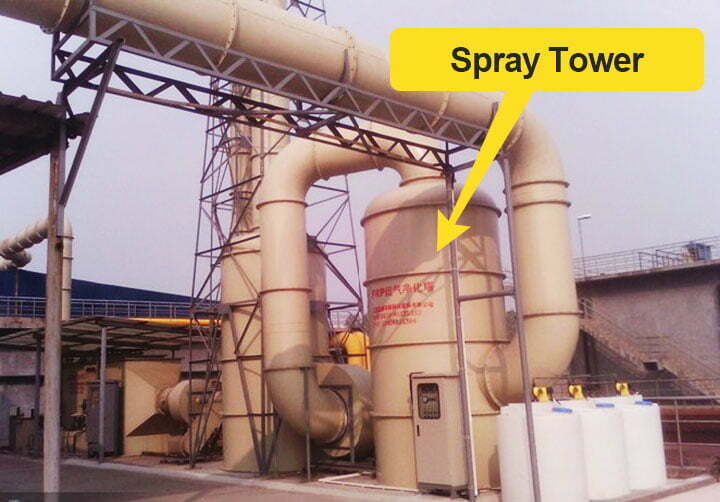

- Programa de tratamento de proteção ambiental

- Nós fornecer ciclone (coletor de poeira), equipamento de desodorização (torre de pulverização, condensador) para ajudar os clientes a responder facilmente às revisões ambientais e cumprir os padrões de emissão locais.

- Personalização e suporte de serviço

- Shuliy pode fornecemos soluções personalizadas completas para linhas de produção de farinha de peixe de acordo com as matérias-primas, locais, orçamentos, etc. dos clientes.

- Além disso, fornecemos instalação e comissionamento, treinamento técnico e serviço pós-venda remoto para garantir a operação longa e estável do equipamento.

Aplicações da linha de produção de farinha de peixe

- Para fazer ração animal. A farinha de peixe pode ser usada no processamento de ração para animais de fazenda. É principalmente usada na produção de ração para porcos, galinhas e gado. A ração para esses animais precisa conter proteína de alta qualidade, especialmente para leitões e pintinhos jovens. Como os animais jovens estão em período de crescimento vigoroso, a demanda por proteína e a proporção de aminoácidos nas proteínas são relativamente altas. A farinha de peixe é uma proteína animal na qual a proporção de aminoácidos é mais próxima dos aminoácidos necessários pelos animais.

- Alimentação de animais aquáticos. O pó de farinha de peixe é usado como matéria-prima principal para proteínas de ração, como peixe, caranguejo e camarão em animais aquáticos. A proporção de aminoácidos necessária na farinha de peixe é a mais próxima. Adicionar farinha de peixe pode garantir que os animais aquáticos cresçam mais rápido.

- Usado para fazer ração para animais de pelagem. A farinha de peixe pode ser usada para fazer ração para alguns animais de pelagem, como raposas e grilos. Animais de pelagem são principalmente carnívoros, e a demanda por proteína é grande em crescimento. A farinha de peixe de alta qualidade como matéria-prima de proteína é a primeira escolha para esses ingredientes de ração animal.

Teste de operação da fábrica de farinha de peixe

A fábrica de farinha de peixe pode secar materiais em pó e granulados com requisitos especiais. Para alcançar uma boa condição, é necessário realizar um experimento de operação de teste da máquina de farinha de peixe.

Os requisitos específicos são os seguintes:

- Inicie o motor principal e garanta que a direção do rolo principal esteja correta.

- Observe se a rotação do rolo principal e os componentes de transmissão estão flexíveis, observe se a entrada e saída de vapor estão conectadas ao equipamento de secagem, e se o manômetro está dentro da faixa de pressão de trabalho.

- Inicie o motor e faça o rolo principal operar suavemente. Após o aumento da temperatura, ajuste a velocidade do motor e a película uniforme no rolo para controlar o teor de água do material.

- Inicie o motor, produza o material de secagem final e ajuste a velocidade do motor de acordo com a quantidade de secagem finalizada.

Após concluir as etapas de operação de teste acima da fábrica de farinha de peixe, se não houver fenômenos anormais, você pode iniciar o uso formal.

Equipamentos compatíveis utilizados na linha de produção de farinha de peixe

Transportador de parafuso na fábrica de farinha de peixe

Nossa fábrica de processamento de farinha de peixe possui um alimentador de parafuso especial, com estrutura simples e baixo custo. É um transportador comumente usado na indústria. O transportador de farinha de peixe é confiável, fácil de manter e ocupa uma área pequena.

Portanto, pode aumentar a eficiência de produção de farinha de peixe e economizar muitos custos de mão de obra.

Na produção industrial, é inevitável produzir alguns gases residuais, fumaça e poeira industrial. Se esses poluentes forem descarregados diretamente na atmosfera, não apenas poluirão o ar, mas também prejudicarão a saúde das pessoas.

Para evitar os problemas acima, equipamos uma unidade de purificação de ar especial na fábrica de farinha de peixe, que é uma torre de pulverização. A torre de pulverização também é conhecida como equipamento de desodorização por pulverização, torre de purificação por pulverização ou lavador de spray. Pode coletar efetivamente poeira e gases nocivos através de múltiplos filtros. O desempenho inovador e avançado do equipamento de farinha de peixe

A inovação e o desempenho avançado da planta de farinha de peixe

- Usamos extração de ar quente em vez do vapor indireto original como fonte de calor, e a eficiência de aquecimento será significativamente melhorada. Espera-se que o consumo de energia economize mais de 30% em relação ao equipamento de processo original.

- A tecnologia de secagem rápida de curto tempo a baixa temperatura pode proteger efetivamente os aminoácidos na farinha de peixe de serem destruídos. Isso reduz a taxa de perda de proteína verdadeira na farinha de peixe de 15-30% para menos de 5%, atingindo ou superando o mesmo padrão de farinha de peixe.

- Nosso projeto é mantido sob pressão negativa fechada, com produção automática contínua, alta eficiência, baixo consumo de energia, sem poluição ao meio ambiente.

Máquina de fabricação de farinha de peixe de 500kg/h colocada em produção na Líbia

A farinha de peixe possui alto teor de proteína e é usada principalmente na alimentação animal. Devido ao seu valor econômico extremamente alto, investidores de vários países começaram a estabelecer fábricas de processamento de farinha de peixe para produzir uma variedade de farinha de peixe de alta qualidade em grande escala.

Recentemente, um cliente líbio fez um pedido conosco. Sua fábrica está localizada à beira-mar e a matéria-prima principal é peixe branco.