شولئی مچھلی کے آٹے کی پیداوار لائن ایک ایسا سامان ہے جو مچھلی کے چھوٹے ٹکڑوں (جیسے مچھلی کا سر، ہڈیاں، اندرونی اعضا وغیرہ) یا تازہ مچھلی کو اعلیٰ پروٹین مچھلی کے آٹے اور مچھلی کے تیل میں تبدیل کرنے کے لیے مخصوص ہے۔ اس کی صلاحیت 1-5t روزانہ، 10-50t روزانہ، 50-100t روزانہ، 100-250t روزانہ، اور اس سے بھی زیادہ ہے۔

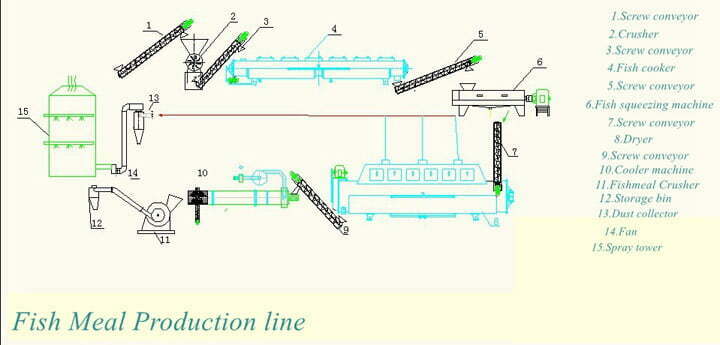

اس مچھلی کے آٹے کی پروسیسنگ پلانٹ میں شامل ہیں: مچھلی کچلنے والی، مچھلی پکانے والی، پیچ پریس، بھاپ خشک کرنے والی، ٹھنڈک اور چھاننے والی مشین، گرائنڈر، اور پیکنگ مشین۔ پیچ پریس کے مرحلے میں، مچھلی کا تیل پیدا ہوتا ہے۔ اگر آپ کو مچھلی کا تیل چاہیے، تو ایک مچھلی کا تیل جدا کرنے والی مشین درکار ہے۔

یہ وسیع پیمانے پر فیڈ پروسیسنگ پلانٹس، آبی زراعت کے فارم، حیوانی پروٹین ری سائیکلنگ پلانٹس اور دیگر صنعتوں میں استعمال ہوتا ہے، اور اس کی سرمایہ کاری پر اعلیٰ منافع اور ماحولیاتی تحفظ کی مضبوط کارکردگی کی خصوصیت رکھتا ہے۔ دلچسپی ہے؟ مزید معلومات کے لیے ہم سے رابطہ کریں!

مچھلی کا آٹا کیا ہے؟

مچھلی کا آٹا ایک بھورا پاؤڈر ہے جو پروٹین اور غذائی اجزاء سے بھرپور ہوتا ہے، جو عام طور پر جانوروں کے کھانے، جیسے بلی اور کتے کے کھانے، خرگوش کے کھانے، اور پولٹری فیڈ کی تیاری میں استعمال ہوتا ہے۔ یہ بنیادی طور پر کچھ مچھلی سے بنایا جاتا ہے جو انسانی استعمال کے لیے مناسب نہیں، چھوٹی مچھلی، مردہ مچھلی یا مچھلی کی پروسیسنگ کے باقیات (مثلاً مچھلی کا سر، ہڈیاں، اندرونی اعضا وغیرہ) سے، کٹائی، بھاپ دینے، دباؤ ڈالنے، خشک کرنے اور دیگر عمل کے بعد۔

اعلی غذائیت اور مارکیٹ کی طلب کی وجہ سے، حالیہ سالوں میں مچھلی کے آٹے کی پیداوار ایک بہت ہی امید افزا کاروبار بن گیا ہے۔

مچھلی کے آٹے کی پیداوار لائن کے ساتھ مچھلی کا آٹا کیسے بنایا جائے؟

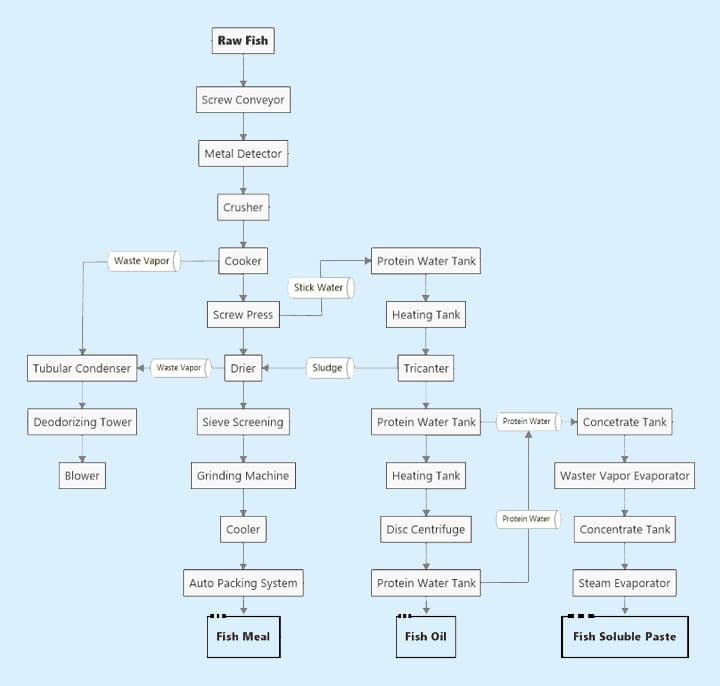

مچھلی کے آٹے کی عام پروسیسنگ کا طریقہ کار شامل ہے: مچھلی کا کاٹنا→مچھلی پکانا→پکڑی ہوئی مچھلی کو نچوڑنا→بھاپ خشک کرنا→مچھلی کے پاؤڈر کو ٹھنڈا کرنا اور چھاننا→مچھلی کے آٹے کو گرائنڈ کرنا→مچھلی کے آٹے کی پیکنگ۔ نچوڑنے کے دوران، مچھلی کا تیل بھی تیار ہوتا ہے۔ کیا آپ کو مچھلی کا تیل چاہیے، تو ایک مچھلی کا تیل جدا کرنے والی مشین درکار ہے۔

پہلا قدم: مچھلی کو کچلنا

یہ مچھلی کا کچلنے والا مچھلی کے چھوٹے ٹکڑوں، تازہ مچھلی، جھینگا، اور کیڑے وغیرہ کو ≤5mm کے چھوٹے سائز میں کاٹنے کے لیے استعمال ہوتا ہے۔ اگر آپ کے خام مال کا سائز چھوٹا ہے، تو آپ اس مرحلے کو چھوڑ سکتے ہیں اور براہ راست اسے پیچ کنویئر کے ذریعے مچھلی کے پکانے والی مشین میں لے جا سکتے ہیں۔

- صلاحیت: 500-1000کلوگرام/گھنٹہ

- طاقت: 5.5 کلو واٹ

- مواصفات: 1200X600X1000mm (لمبائی، چوڑائی اور اونچائی)

- وزن: 300کلوگرام

- مشین کا بیرونی حصہ سٹینلیس اسٹیل سے بنا ہے اور چاقو 40Cr سے بنے ہیں۔

- اوپر کے حصے میں ایک جمع کرنے والا ہاپر نصب ہے، جو SUS304 سٹینلیس اسٹیل سے بنا ہے۔

دوسرا قدم: مچھلی کو پکانا

یہ مچھلی پکانے والی مشین بھاپ حرارت کے طریقہ کار کو اپناتی ہے، لہٰذا اسے بھاپ کا ذریعہ فراہم کرنے والے بوائلر کے ساتھ ملانا چاہیے۔ یہ بوائلر خریدا جا سکتا ہے یا صارفین خود بنا سکتے ہیں۔ یہ مچھلی پکانے کا مرحلہ مچھلی کے آٹے کی پروسیسنگ کے لیے دو اہم کام انجام دیتا ہے: پکانا اور جراثیم کشی۔

- پکانے کا وقت: 20 منٹ

- پکانے کا درجہ حرارت: 150℃-160℃

- اندرونی سلنڈر Q345 کاربن اسٹیل سے بنا ہے جس کی موٹائی 10mm ہے۔

- باہر کا سلنڈر Q235 اسٹیل پلیٹ سے بنا ہے جس کی موٹائی 8mm ہے۔

- اس میں برانڈڈ سوئول جوائنٹس اور سٹینلیس اسٹیل ہوزز شامل ہیں۔

- ایک ٹکڑا بیم کے ساتھ، حفاظتی ریل اور چڑھنے والی سیڑھی کے ساتھ دستیاب ہے۔

تیسرا قدم: پکڑی ہوئی مچھلی کو نچوڑنا

پکڑی ہوئی مچھلی کے ٹکڑوں کو پھر مچھلی نچوڑنے والی مشین میں منتقل کیا جاتا ہے تاکہ پانی اور مچھلی کے چربی کو تیزی سے نکالا جا سکے۔ یہ پیچ پریس مشین مچھلی کے رس، جیسے مچھلی کا تیل اور پانی، کو زیادہ سے زیادہ نکال سکتی ہے، اور باریک مچھلی کے گوشت اور مچھلی کے باقیات کو slag خارج کرنے والے آؤٹ لیٹ سے خارج کرتی ہے۔

- آخری مصنوعات: خام اور گیلا مچھلی کا آٹا اور نکالا ہوا تیل-پانی کا مکسچر

- اسپیرل بلیڈ کا قطر 18mm ہے، اور اسپیرل بلیڈ کی موٹائی 12mm ہے، مواد 16MnR۔

- باہر کا کور اور نچلے وصولی کے ٹین 304 سٹینلیس اسٹیل پلیٹ سے بنے ہیں۔

- اختیاری میچ شدہ آلات: مچھلی کا تیل جدا کرنے والی مشین

چوتھا قدم: مچھلی کے پاؤڈر کو خشک کرنا

دباؤ کے بعد، مچھلی کے باقیات میں اب بھی کچھ پانی ہوتا ہے۔ اس لیے، ہمیں تیز خشک کرنے کے لیے مچھلی کے آٹے کی خشک کرنے والی مشین استعمال کرنی چاہیے۔ یہ روٹری ڈرائر مشین اپنی گردش کے دوران، بوائلر کے بھاپ کے حرارت سے، مچھلی کے آٹے کو تیزی سے خشک کر سکتی ہے۔ اس مشین کا مکمل بند ڈھانچہ ہے اور اس میں دھول جمع کرنے والا شامل ہے، جو دھول آلودگی پیدا نہیں کرے گا۔

- خشک کرنے کا طریقہ: بھاپ خشک کرنا

- باہر کے سلنڈر کا مواد Q235 کاربن اسٹیل ہے، موٹائی مکمل مچھلی کے آٹے کی پیداوار لائن کی صلاحیت کے مطابق ہے۔

- آلات کا بیرونی جیکٹڈ ڈھانچہ ہے۔

- حرارتی موصلیت کا مواد ایلومینا سلیکیٹ ہے، اور موصلیت بورڈ SUS304 سٹینلیس اسٹیل ہے۔

پانچواں قدم: مچھلی کے آٹے کی چھاننا اور دوبارہ کچلنا

مچھلی کے آٹے کی پیداوار لائن میں، خشک کرنے کے بعد، مچھلی کے آٹے کو ایک ڈرم چھاننے والی مشین سے چھاننا چاہیے تاکہ برابر سائز کا مچھلی کا پاؤڈر حاصل کیا جا سکے۔ ڈرم چھاننے والی مشین کو مختلف چھاننے کے جالوں کے ساتھ تبدیل کیا جا سکتا ہے۔

- افعال: ٹھنڈک اور چھاننا، دو سطحوں میں خارج

- سٹینلیس اسٹیل کا جال، سائز: 5mmX5mm

- اسٹینڈ Q235B سے بنا ہے، اور مرکزی جسم SUS304 سے، δ=2mm۔

چھاننے کے بعد، باریک مچھلی کے پاؤڈر کو پیک کیا جا سکتا ہے، اور جو مچھلی کا پاؤڈر مطلوبہ سائز (عام طور پر 3mm) کا نہیں ہوتا، اسے ایک چھوٹے کچلنے والی مشین کے ذریعے دوبارہ کچلا جا سکتا ہے تاکہ آلودگی سے پاک ماحول کو یقینی بنایا جا سکے۔

- صلاحیت: 600-800کلوگرام/گھنٹہ (9FQ40-28)

- قومی مچھلی کے آٹے کے معیار کے مطابق پیسنے کا سائز

- T12 اوزار کے اسٹیل سے بنا، اچھی Abrasion مزاحمت کے ساتھ

چھٹا قدم: مچھلی کے آٹے کی پیکنگ

آخری مچھلی کا آٹا دستی طور پر بیگ میں بند کیا جا سکتا ہے یا خودکار پیکنگ مشین کے ذریعے انفرادی چھوٹے پیکجوں میں۔ ہم خصوصی پیکجنگ مشین فراہم کر سکتے ہیں تاکہ مچھلی کے آٹے کی مصنوعات کو اعلیٰ کارکردگی کے ساتھ مقدار کے مطابق پیک کیا جا سکے، اور اس پر کسٹم لوگو، حروف، برانڈز، تصاویر وغیرہ بھی شامل کی جا سکتی ہیں۔

- ماڈل: TZ-DGS-50F

- مواد درخواست: پاؤڈر، مخلوط مواد

- پیکنگ کی حد: 5-50کلوگرام

- درستگی: ±0.2-0.5%

- پیکنگ کی رفتار: 3-8 بیگ/منٹ

- ہوا کا دباؤ/گیس کا استعمال: 0.4-0.6MPa/1 m3/h

- طاقت: 380V/2.6KW

- ابعاد: 3000×1500×2500 ملی میٹر

شولئی مچھلی کے آٹے کی پیداوار لائن کے اہم فوائد

- مختلف پیداوار کی صلاحیتیں

- ہمارا مچھلی کے آٹے کا مشین ہے ایک دن میں 1-5 ٹن، 10-50 ٹن، 50-100 ٹن یا اس سے زیادہ کی پیداوار. ہم اپنے صارفین کی اصل ضروریات کے مطابق مختلف مچھلی کے آٹے کی پیداوار لائنیں تخصیص کر سکتے ہیں۔

- معیاری SUS 304 سٹینلیس اسٹیل مواد

- شولئی مچھلی کے آٹے کے پلانٹ میں تمام آلات SUS 304 سٹینلیس اسٹیل مواد، جو زنگ سے بچاؤ اور پائیدار ہیں۔ اس طرح، مشین کو طویل عرصے تک استعمال کیا جا سکتا ہے۔

- اعلی معیار کا مچھلی کا آٹا اور مچھلی کا تیل زیادہ آمدنی کے لیے

- شولئی مچھلی کے آٹے کے پروسیسنگ پلانٹ کا استعمال اس بات کو یقینی بناتا ہے کہ مچھلی کے آٹے میں پروٹین کا مواد 60% تک ہوتا ہے۔ یا زیادہ، جس میں پروٹین کی مقدار زیادہ، آلودگی کم، جذب میں آسان، اور مارکیٹ قیمت زیادہ ہے۔

- نکالا ہوا خالص مچھلی کا تیل کاسمیٹکس، فارماسیوٹیکلز، اور صحت کی دیکھ بھال کے مصنوعات کے میدان میں استعمال کیا جا سکتا ہے، خام مال کی زیادہ سے زیادہ قیمت کو سمجھنا اور صارفین کے منافع میں اضافہ کرنا۔

- ماحولیاتی تحفظ کا علاج پروگرام

- ہم سائکلون (دھول جمع کرنے والا)، ڈیورڈینگ آلات (اسپرے ٹاور، کنڈینسر) مقصد ہے کہ صارفین آسانی سے ماحولیاتی جائزہ کا جواب دے سکیں اور مقامی اخراج کے معیار کی تعمیل کریں۔

- حسب ضرورت اور سروس سپورٹ

- شولئی ایک اسٹاپ کسٹمائزڈ حل فراہم کریں مچھلی کے آٹے کی پیداوار لائنوں کے لیے، صارفین کے خام مال، مقامات، بجٹ وغیرہ کے مطابق۔

- مزید برآں، ہم تنصیب اور کمیشننگ، تکنیکی تربیت اور ریموٹ بعد از فروخت سروس فراہم کرتے ہیں تاکہ آلات کا طویل مدتی اور مستحکم آپریشن یقینی بنایا جا سکے۔

مچھلی کے آٹے کی پیداوار لائن کے استعمالات

- جانوروں کے لیے خوراک بنانے کے لیے۔ مچھلی کے آٹے کا پاؤڈر جانوروں کے کھانے، جیسے سور، مرغی، اور گائے کے لیے پروٹین کے خام مال کے طور پر استعمال ہوتا ہے۔ ان جانوروں کے لیے خوراک میں اعلیٰ معیار کا پروٹین شامل ہونا ضروری ہے، خاص طور پر چھوٹے سور اور مرغیوں کے لیے۔ کیونکہ جوان جانور تیزی سے بڑھ رہے ہوتے ہیں، پروٹین کی طلب اور پروٹین میں امینو ایسڈ کا تناسب نسبتاً زیادہ ہوتا ہے۔ مچھلی کا آٹا ایک حیوانی پروٹین ہے جس میں امینو ایسڈ کا تناسب ان امینو ایسڈز کے قریب ترین ہے جو جانوروں کو درکار ہوتے ہیں۔

- آبی جانوروں کے لیے خوراک۔ مچھلی کے آٹے کا پاؤڈر آبی جانوروں جیسے مچھلی، جھینگا، اور کیکڑے کے لیے خوراک کے پروٹین کے بنیادی خام مال کے طور پر استعمال ہوتا ہے۔ مچھلی کے آٹے اور آبی جانوروں کے لیے ضروری امینو ایسڈ کا تناسب سب سے قریب ہے۔ مچھلی کے آٹے کا استعمال آبی جانوروں کی تیزی سے نشوونما کو یقینی بناتا ہے۔

- بالوں والے جانوروں کے لیے خوراک بنانے کے لیے استعمال ہوتا ہے۔ مچھلی کا پاؤڈر کچھ بالوں والے جانوروں جیسے لومڑی اور جھینگا کے لیے خوراک بنانے کے لیے استعمال کیا جا سکتا ہے۔ بالوں والے جانور زیادہ تر گوشت خور ہوتے ہیں، اور پروٹین کی طلب میں اضافہ ہو رہا ہے۔ اعلیٰ معیار کا مچھلی کا آٹا پروٹین کے خام مال کے طور پر ان جانوروں کی خوراک کے اجزاء کے لیے اولین انتخاب ہے۔

مچھلی کے آٹے کی مشین کا ٹیسٹ آپریشن

مچھلی کے آٹے کا پلانٹ مخصوص ضروریات کے مطابق پاؤڈر اور دانہ دار مواد کو خشک کر سکتا ہے۔ اچھے حالات حاصل کرنے کے لیے، مچھلی کے آٹے کی مشین کا ٹیسٹ آپریشن تجربہ ضروری ہے۔

مخصوص ضروریات درج ذیل ہیں:

- مرکزی موٹر شروع کریں اور یقینی بنائیں کہ مرکزی رولر کی سمت درست ہے۔

- چیک کریں کہ مرکزی رولر اور ٹرانسمیشن کے اجزاء کی گردش ہموار ہے، بھاپ کا داخلہ اور خارجہ کنکشن خشک کرنے والے آلات سے ہے یا نہیں، اور پریشر گیج کام کے پریشر رینج میں ہے یا نہیں۔

- موٹر شروع کریں، اور مرکزی رولر ہموار چلتا ہے۔ درجہ حرارت بڑھنے کے بعد، موٹر کی رفتار کو ایڈجسٹ کریں اور رولر پر یکساں فلم کو کنٹرول کریں تاکہ مواد کا پانی کا مواد کنٹرول کیا جا سکے۔

- موٹر شروع کریں، خشک شدہ مواد کو باہر نکالیں، اور مکمل خشک شدہ مقدار کے مطابق موٹر کی رفتار کو ایڈجسٹ کریں۔

اوپر دیے گئے تجرباتی آپریشن کے مراحل مکمل کرنے کے بعد، اگر کوئی غیر معمولی بات نہ ہو، تو آپ باقاعدہ استعمال شروع کر سکتے ہیں۔

مچھلی کے آٹے کی پیداوار لائن میں استعمال ہونے والا میچ شدہ سامان

مچھلی کے آٹے کے پلانٹ میں پیچ کنویئر

ہمارا مچھلی کے آٹے کا پروسیسنگ پلانٹ ایک خاص پیچ کنویئر رکھتا ہے، جس کا ساخت سادہ اور کم قیمت ہے۔ یہ ایک صنعتی طور پر استعمال ہونے والا کنویئر ہے۔ مچھلی کے آٹے کا کنویئر قابل اعتماد، آسان دیکھ بھال، اور کم جگہ لیتا ہے۔

لہٰذا، یہ مچھلی کے پاؤڈر کی پیداوار کی کارکردگی کو بڑھا سکتا ہے اور بہت زیادہ محنت کی لاگت کو بچا سکتا ہے۔

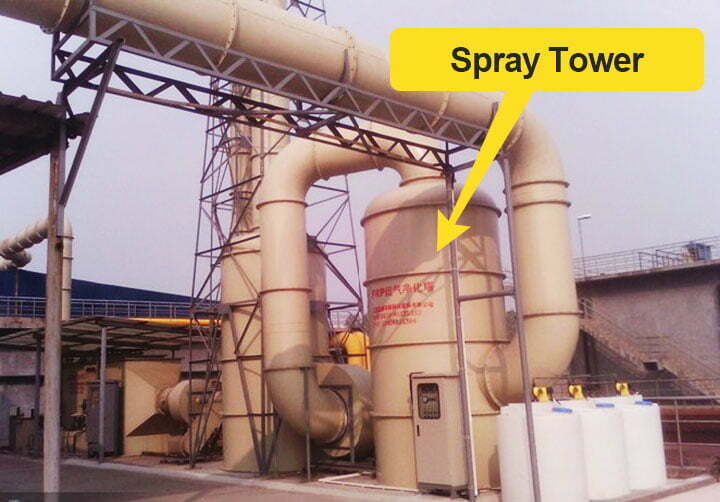

صنعتی پیداوار میں، کچھ فضلہ گیس، دھواں اور صنعتی دھول پیدا ہونا ناگزیر ہے۔ اگر ان آلودگیوں کو براہ راست فضا میں خارج کیا جائے، تو یہ ہوا کو آلودہ کرنے کے ساتھ ساتھ لوگوں کی صحت کو بھی نقصان پہنچائیں گے۔

اوپر دی گئی مسائل سے بچاؤ کے لیے، ہم نے مچھلی کے آٹے کے پروسیسنگ پلانٹ میں ایک خاص ہوا صاف کرنے والی یونٹ نصب کی ہے، جسے سپرے ٹاور بھی کہا جاتا ہے۔ یہ سپرے ٹاور اسپرے ڈیورڈینٹ آلات، اسپرے کلیننگ ٹاور یا اسپرے اسکربر کے طور پر بھی جانا جاتا ہے۔ یہ متعدد فلٹرز کے ذریعے دھول اور نقصان دہ گیسوں کو مؤثر طریقے سے جمع کر سکتا ہے۔ مچھلی کے آٹے کے آلات کی جدت اور جدید کارکردگی۔

مچھلی کے آٹے کے پلانٹ کی جدت اور جدید کارکردگی

- ہم ہاٹ ایئر نکالنے کا استعمال کرتے ہیں، جو اصل غیر مستقیم بھاپ کے بجائے، خشک حرارت کا ذریعہ ہے، اور حرارتی کارکردگی میں نمایاں بہتری آئے گی۔ توقع ہے کہ توانائی کی کھپت 30% سے زیادہ بچ جائے گی۔

- کم درجہ حرارت تیز اور مختصر وقت خشک کرنے کی ٹیکنالوجی مچھلی کے آٹے میں امینو ایسڈ کو تباہ ہونے سے مؤثر طریقے سے بچا سکتی ہے۔ اس سے مچھلی کے آٹے میں اصل پروٹین کا نقصان 15-30% سے کم ہو کر 5% سے بھی کم ہو جاتا ہے، اور یہ معیار یا اس سے بھی بہتر ہوتا ہے۔

- ہمارا ڈیزائن ریاستی سطح پر بند منفی دباؤ کے تحت رکھا گیا ہے، مسلسل خودکار پیداوار، اعلیٰ کارکردگی، کم توانائی استعمال، اور ماحول کو آلودہ کیے بغیر۔

لیبیا میں 500کلوگرام/گھنٹہ مچھلی کے آٹے کی مشین کو پیداوار میں لایا گیا

مچھلی کے آٹے کا معیار زیادہ پروٹین مواد رکھتا ہے اور بنیادی طور پر جانوروں کے کھانے میں استعمال ہوتا ہے۔ اس کی بہت زیادہ اقتصادی قیمت کی وجہ سے، بہت سے ممالک میں سرمایہ کاروں نے بڑے پیمانے پر اعلیٰ معیار کے مچھلی کے آٹے کی پروسیسنگ پلانٹس قائم کرنا شروع کر دیے ہیں۔

حال ہی میں، ایک لیبیائی صارف نے ہم سے آرڈر دیا ہے۔ اس کا فیکٹری سمندر کے کنارے واقع ہے اور اس کا بنیادی خام مال سفید مچھلی ہے۔