Shuliy 鱼粉生产线是一套专门将鱼 scraps(如鱼头、鱼骨、鱼内脏等)或鲜鱼转化为高蛋白鱼粉和鱼油的设备。其产能为每天1-5吨、10-50吨、50-100吨、100-250吨,甚至更大。

该鱼粉加工厂包括鱼破碎机、鱼煮锅、螺旋压榨机、蒸汽干燥机、冷却筛分机、研磨机和包装机。在螺旋压榨步骤中,鱼油被提取。如果您想要鱼油,则需要鱼油分离器。

广泛用于饲料加工厂、水产养殖场、动物蛋白回收厂等行业,具有高投资回报率和强环保效率。感兴趣吗?欢迎联系我们获取更多信息!

什么是鱼粉?

鱼粉是一种富含蛋白质和营养的棕色粉末,通常用于动物饲料的生产,如猫狗粮、兔粮和家禽饲料。它主要由一些不适合人类食用的小鱼、死鱼或鱼加工残渣(如鱼头、鱼骨、内脏等)经过切割、蒸煮、压榨、干燥等工艺制成。

由于其高营养价值和市场需求,鱼粉生产在近年来已成为一个非常有前景的行业。

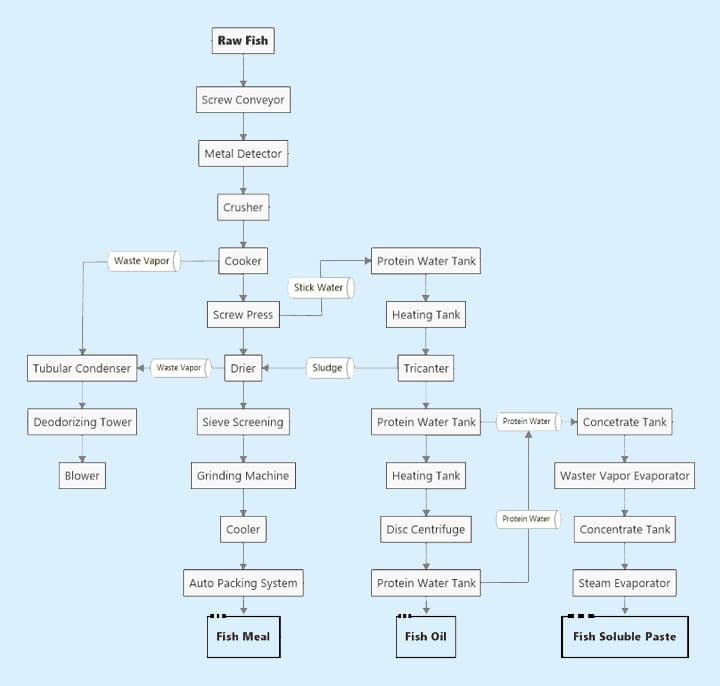

如何使用鱼粉生产线制作鱼粉?

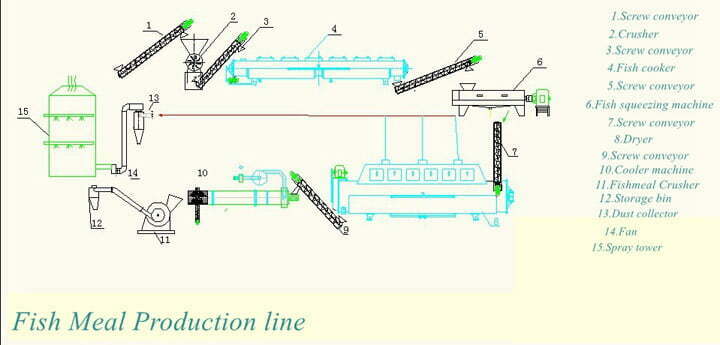

常见的鱼粉加工程序包括鱼切割→鱼烹饪→熟鱼挤压→蒸汽干燥→鱼粉冷却筛选→鱼粉研磨→鱼粉包装。在鱼挤压过程中,鱼油被提取。看看您是否需要鱼油分离器。

第一步:鱼破碎

该鱼破碎机用于将鱼 scraps、鲜鱼、虾和虫子等切割成≤5mm的小块。如果您的原材料尺寸较小,可以跳过此步骤,直接通过螺旋输送机将其运输到鱼煮锅。

- 产能:500-1000kg/h

- 功率:5.5 kW

- 规格:1200X600X1000mm(长、宽、高)

- 重量:300kg

- 机器外壳由不锈钢制成,刀具由40Cr制成。

- 上部配有一个集料斗,由SUS304不锈钢制成。

第二步:鱼烹饪

该鱼煮锅采用蒸汽加热方式,因此应与锅炉配合使用,以提供蒸汽源。锅炉可以由客户自行购买或自建。该鱼烹饪步骤主要有两个功能:加工鱼粉:熟化和灭菌。

- 烹饪时间:20分钟

- 烹饪温度:150℃-160℃

- 内筒由Q345碳钢制成,厚度为10mm。

- 外筒由8mm壁厚的Q235钢板制成。

- 配备品牌旋转接头和不锈钢软管。

- 一体式支架,增加护栏和爬梯可用。

第三步:熟鱼挤压

熟鱼块随后被运输到鱼挤压机中,快速挤出水分和鱼脂。该螺旋压榨机可以最大限度地挤出鱼油和水等汁液产品,并从渣料排出细碎的鱼肉和鱼残渣。

- 最终产品:粗湿鱼粉和提取的油水混合物

- 螺旋刀片直径为18mm,螺旋刀片厚度为12mm,材料为16MnR。

- 外壳和底部接收槽由304不锈钢板制成。

- 可选配套设备:鱼油分离器

第四步:鱼粉干燥

压榨后,鱼残渣仍有一定的水分。因此,我们应使用鱼粉干燥机进行快速干燥。该旋转干燥机可以在其旋转过程中快速干燥鱼粉,热源为锅炉蒸汽。该干燥机具有全封闭结构,并配有除尘器,不会产生粉尘污染。

- 干燥方法:蒸汽干燥

- 外筒材料为Q235碳钢,厚度与整个鱼粉生产线的产能相匹配。

- 设备为外套结构。

- 保温材料为铝硅酸盐,保温板为SUS304不锈钢。

第五步:鱼粉筛选和再粉碎

在鱼粉生产线中,干燥后,鱼粉应通过滚筒筛分机筛选,以获得均匀尺寸的鱼粉。滚筒筛分机可以更换不同筛网,具有不同筛孔。

- 功能:冷却和筛选,分两级排出

- 不锈钢网,尺寸:5mmX5mm

- 支架由Q235B制成,主体由SUS304制成,δ=2mm。

筛选后,细鱼粉可以包装,不符合要求尺寸(通常为3mm)的鱼粉可以通过带有除尘器的小型破碎机再次粉碎,以确保无污染环境。

- 产能:600-800kg/h(9FQ40-28)

- 研磨尺寸符合国家鱼粉标准

- 由T12工具钢制成,具有良好的耐磨性

第六步:鱼粉包装

最终鱼粉可以手动装袋或通过自动包装机包装成单独的小包装。我们可以提供专门的包装机,用于高效定量包装鱼粉产品,并带有定制的标志、字母、品牌、图片等。

- 型号:TZ-DGS-50F

- 应用材料:粉末、混合材料

- 填充范围:5-50kg

- 精度:±0.2-0.5%

- 包装速度:3-8袋/分钟

- 气压/气体消耗:0.4-0.6MPa/1 m3/h

- 功率:380V/2.6KW

- 尺寸:3000×1500×2500 mm

Shuliy鱼粉生产线的主要优势

- 各种生产能力

- 我们的鱼粉机具有 每天产出1-5吨、10-50吨、50-100吨或更多. 我们可以根据客户的实际需求定制不同的鱼粉生产线。

- 优质SUS 304不锈钢材料

- Shuliy鱼粉厂的所有设备均采用 SUS 304不锈钢材料, 具有耐腐蚀和耐用性。因此,该机器可以长期使用。

- 高质量鱼粉和鱼油带来高收益

- 使用Shuliy鱼粉加工厂确保了 鱼粉的蛋白质含量高达60% 或更多,含有高蛋白,杂质少,易于吸收,市场价格更高。

- 提取的纯鱼油可用于化妆品、药品和保健品领域,实现原材料的最大价值,提高客户的盈利能力。

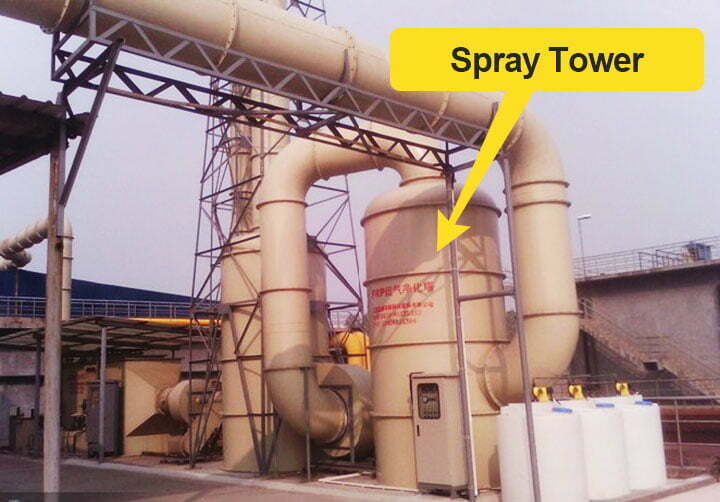

- 环保处理方案

- 我们 提供旋风分离器(除尘器)、除臭设备(喷雾塔、冷凝器) 帮助客户轻松应对环境审查,遵守当地排放标准。

- 定制和服务支持

- Shuliy可以 提供一站式定制解决方案 根据客户的原材料、场地、预算等提供鱼粉生产线的定制解决方案。

- 此外,我们提供安装和调试、技术培训和远程售后服务,以确保设备的长期稳定运行。

鱼粉生产线的应用

- 用于制作牲畜饲料。鱼粉可用于牲畜饲料的加工。主要用于生产猪、鸡和牛等动物的饲料。这些动物的饲料需要含有高质量的蛋白质,尤其是对于幼猪和小鸡。因为幼年动物正处于快速生长阶段,对蛋白质的需求和蛋白质中氨基酸的比例相对较高。鱼粉是一种动物蛋白,其氨基酸比例最接近动物所需的氨基酸。

- 用于水生动物的饲料。鱼粉粉末作为鱼、螃蟹和虾等水生动物饲料蛋白质的主要原料。鱼粉和水生动物所需的氨基酸比例最接近。添加鱼粉可以确保水生动物生长更快。

- 用于制作毛皮动物的饲料。鱼粉可以用于制作一些毛皮动物(如狐狸和蟋蟀)的饲料。毛皮动物大多是肉食性的,生长过程中对蛋白质的需求很大。高质量的鱼粉作为蛋白质原料是这些动物饲料成分的首选。

鱼粉机厂的试运行

鱼粉厂可以干燥具有特殊要求的粉末和颗粒材料。为了达到良好的状态,需要对鱼粉机进行试运行实验。

具体要求如下:

- 启动主电机,确保主辊正确转向。

- 观察主辊和传动部件的旋转是否灵活,观察蒸汽进出口是否连接到干燥设备,压力表是否在工作压力范围内。

- 启动电机,主辊平稳运行。温度升高后,调整电机速度和辊上的均匀薄膜以控制物料水分。

- 启动电机,输出干燥成品,并根据干燥成品的数量调整电机速度。

在完成鱼粉厂的上述试运行步骤后,如果没有异常现象,可以开始正式使用。

鱼粉生产线中使用的配套设备

在工业生产中,产生一些废气、烟雾和工业粉尘是不可避免的。如果这些污染物直接排放到大气中,不仅会污染空气,还会危害人们的健康。

为防止上述问题,我们在鱼粉加工厂配备了专用空气净化装置,即喷雾塔。喷雾塔也称为喷雾除臭设备、喷雾净化塔或喷雾洗涤器。它可以通过多个过滤器有效收集粉尘和有害气体。鱼粉设备的创新和先进性能

鱼粉厂的创新和先进性能

- 我们使用热风提取代替原来的间接蒸汽作为干热源,供热效率将显著提高。预计能耗将比原工艺设备节省30%以上。

- 低温快速短时间干燥技术可以有效保护鱼粉中的氨基酸不被破坏。这将使鱼粉中真实蛋白质的损失率从原来的15-30%降低到5%以下,达到或超过同类鱼粉标准。

- 我们的设计保持在封闭负压状态下,具有连续自动生产、高效率、低能耗、对环境无污染。

500kg/h鱼粉生产机在利比亚投入生产

鱼粉含有高蛋白,主要用于动物饲料。由于其极高的经济价值,许多国家的投资者已开始建立鱼粉加工厂,以大规模生产各种高质量的鱼粉。

最近,一位利比亚客户向我们下了订单。他的工厂位于海边,主要原料是白鱼。