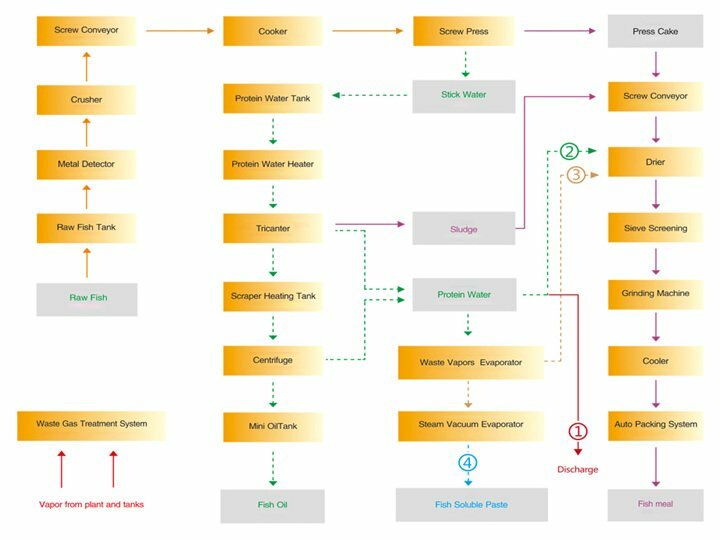

In our fish powder production line,We can get the fish juice Through the fish crushing machine . After the three-phase separation of slag, oil and water, we obtained the protein water.

As a leading brand in the fish powder industry, we can provide 4 different process schemes, and choose the corresponding supporting equipment to handle protewater. We can meet the customer investment scale, factory location, environmental protection requirements and other specific requirements.

4 different treatment of protewater

- 1:Discharge the protein water directly

- 2:Protein water is directly recycled to the dryer.

- 3:Protein water is all recycled to the dryer after concentration.

- 4:concentrated the Protein water to produce a fish-soluble slurry.

Advantages and disadvantages of the above 4 schemes:

- The disadvantage of the first plan was that proteolate emissions not only pollute the environment, but also waste resources, and had a low fish meal gain rate (1: 5). The advantage is that the investment cost of fish powder equipment is low.

- Although the second Scheme increases the equipment investment cost (dryer) compared to Scheme,it improves the yield rate of fish powder (1: 4), reasonable use of resources.

- The third Scheme increases the cost of investment (waste gas concentration equipment) compared to the second Scheme,but it not only has the same fish powder gain rate (1: 4), but also saves energy.

- The equipment investment cost of the last scheme is increased over the third one. Its advantage is that fish slurry products were obtained at the same rate (1: 5) as the first plan.