Raw materials of 300kg/h fish meal machine

This small fish meal plant uses fresh phoenix worms as its raw materials. It can process 300kg of raw materials per hour, and the finished product is high protein feed.

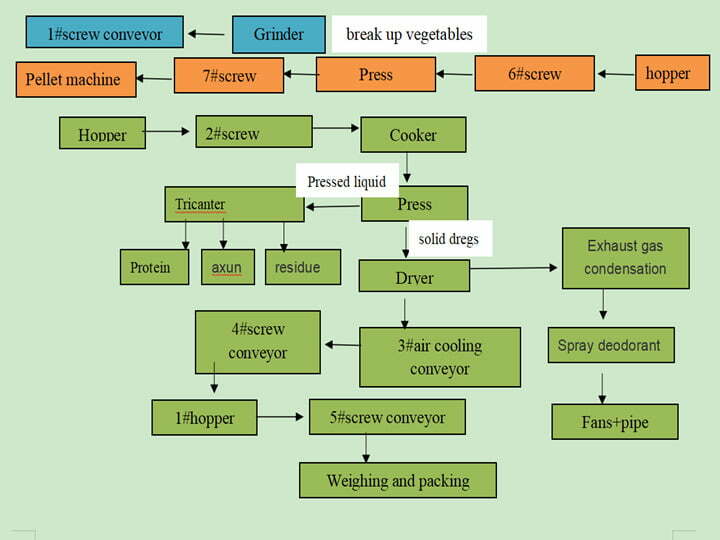

flowing chart

Equipment parameters

The whole set of fish meal production plant mainly includes fish crusher, fish cooker, screw press, fish meal dryer, and corresponding auxiliary equipment. It is heated by 0.5 ton steam boiler, and the fuel can be coal, oil, and natural gas. Its working pressure is 0.7MPa,and the working voltage is 380v, 50hz. The specific parameters of the relevant equipment are as follows.

| Item | Fish meal machine and specification | QTY | POWER KW |

| 1 | Mobile screw conveyor 1# GX 200X3000 Specification ●full SUS304,thickness δ=3mm,δ=4mm ●with hopper and wheels and brake ●size:3500×300×300mm | 1 | 1.5 |

| 2 | Grinder Size:1200X600X1000mm) ●Blade material:40Cr ●capacity:500kg-1000kg/h, finished size:30mm; Motor power:5.5kw | 1 | 5.5 |

| 3 | Round pipe screw conveyor 2# GX 219X4500 Main configuration and parameters ●The outer casing is made of SUS304 stainless steel, δ=3mm, and the blade is made of SUS304 stainless steel, δ=4mm; The spindle is made of SUS304 stainless steel tube ●Function:feed the material in the bin to the cooking machine ●dimension:5000×200×200mm | 1 | 2.2 |

| 4 | Cooking machine: φ426×4000 The equipment spindle adopts φ273×10 seamless steel pipe, the inner cylinder is made of Q345R carbon steel and has a thickness of 10mm. The outer jacket of the equipment is made of Q235 carbon steel. The thickness of 8mm is insulated by stainless steel 304 and the thickness is 0.7mm. | 1 | 2.2 |

| 5 | Press buffer tank volume 0.3m³ material:304stainless steel thickness 2mm | 1 | |

| 6 | Dryer :φ820×4000;The main shaft of the equipment adopts φ273×12 seamless steel pipe. The inner cylinder body is made of Q345R carbon steel material with a thickness of 10mm. The outer jacket of the equipment is made of Q235B carbon steel. The thickness is 8mm. The jacket and shaft and coil are filled with steam heat and external insulation. Stainless steel 304 was used with a thickness of 0.7 mm; V = 20 rpm. With swivel joints and wire hoses. | 1 | 7.5 |

| 7 | Air-cooled U-shaped screw conveyor3# Φ200×4500 Main configuration and parameters ●The outer casing is made of SUS304 stainless steel, δ=3mm; the blade is made of SUS304 stainless steel, δ=4mm; the main shaft is made of seamless SUS304 stainless steel pipe. ●The upper cover is equipped with 304 stainless steel ventilation pipe, Shakron dust collector and induced draft fan for air cooling. ●function:The dried material is sent to a horizontal screw conveyor and cool the material. ●dimension:5000×200×200mm | 1.1 | |

| 8 | Round pipe screw conveyor 4# GX 219X3000 Main configuration and parameters ●The outer casing is made of SUS304 stainless steel, δ=3mm, the blade is made of SUS304 stainless steel, δ=4mm; the main shaft is made of SUS304 stainless steel tube. ●function:Horizontal conveying material to vacuum bin1# ●dimension:2000×200×200mm; | 1.5 | |

| 9 | Vacuum bin #1 ●material:304stainless steel,thickness: 4mm ●volume:1m³ ●Equipped with feeding screw conveyor | 1.5 | |

| 10 | Round pipe screw conveyor 5# GX 219X5000 Main configuration and parameters ●The shell is made of SUS304 stainless steel, =3mm, the blade is made of SUS304 stainless steel, =4mm; The spindle is made of seamless SUS304 stainless steel tube ●function:Send the material in vacuum bin # 1 to the packing machine ●dimension:5500×200×200mm; | 3 | |

| 11 | Vacuum bin 2# ●material:Q235B carbon steel,thickness 6mm ●volume:1m³ ●Equipped with feeding screw conveyor | 1.5 | |

| 12 | Round pipe screw conveyor 6# GX 219X2500 Main configuration and parameters ●The shell is made of SUS304 stainless steel, =3mm, the blade is made of SUS304 stainless steel, =4mm; The spindle is made of SUS304 stainless steel tube ●function:Send the material from the vacuum bin # 1 to the press machine ●dimension:3000×200×200mm; | 1.5 | |

| 13 | Round pipe screw conveyor 7# GX 219X2500 Main configuration and parameters ●The shell is made of SUS304 stainless steel, =3mm, the blade is made of SUS304 stainless steel, =4mm; The spindle is made of SUS304 stainless steel tube ●function:convey the pressed material to the granulator ●dimension:3000×200×200mm; | 1.5 | |

| 14 | Screen machine Φ800×2000 Main configuration and parameters ●frame is made of Q235B material,main part is made of SUS304 stainless steel δ=2mm; ●The material is cooled and screened, and the material is discharged in two stages ,screen hole 3mm. ●dimension: 2.4X1.1X1.7m | 1 | 1.5 |

| 15 | Cyclone System :Φ600×1500,δ=2.0mm,SUS304; | 1 | |

| 16 | Cooling tower: capacity50m3/h,FRP material,fan 1.5kw | 1 | 1.5 |

| 17 | Heat exchange ●Φ800×4000, cover 304stainless steel, thickness 4mm,cooling pipe: 304stainless steel, Φ32×2.0, Working square:48㎡ ●3kw recycling water pump | 3 | |

| 18 | Cooling water circulation tank : On-site concrete fabrication Dimension: 300030002000 | 1 | |

| 19 | spray tower Φ1000X3500 ●All made of fiberglass,δ=8mm; ●Equipped with sprinkler head, corrosion resistant packing, ●Configuration of pump,power:P=1.5kw; The washing liquid is sprayed down from the top of the tower in the form of fog (or small droplets), and the exhaust gas is sprayed up from the bottom of the tower to reach the purpose of gas-liquid contact. After the treatment in the defogging section, the particles and odor in the exhaust gas are removed and finally discharged into the atmosphere. | 1 | 1.5 |

| 20 | 3kw Stainless steel induced draft fan y6-41,3kw 304 Stainless steel exhaust pipe Φ200×1.2,The trace is calculated at 20 meters | 1 | 3 |

| 21 | electrical control cabinet Main configuration and parameters ● zhengtai brand Electrical components, reliable performance; ●Operation indicator light of electrical control box; | 1 | |

| 22 | Equipment installation materials ●Interconnection pipes of equipment in the workshop: steam pipes; ●nstruments, valves: globe valves, pressure gauges, rotary joints, steel hose, etc ●Connection flange, bolt, screw, metal winding pad. ●onnecting wires and cables between equipment and control cabinet; | 1 | |

| 23 | TZ-DGS-50F Application materials: Powder, mixed material Filling range: 5-50kg package precision: ±0.2-0.5% Packing speed:3-8 bags/min Air pressure/gas consumption: 0.4-0.6Mpa/ 1 m3/h Power: 380V/2.6KW Dimension: 3000×1500×2500 (mm) | 1 | 2.6 |