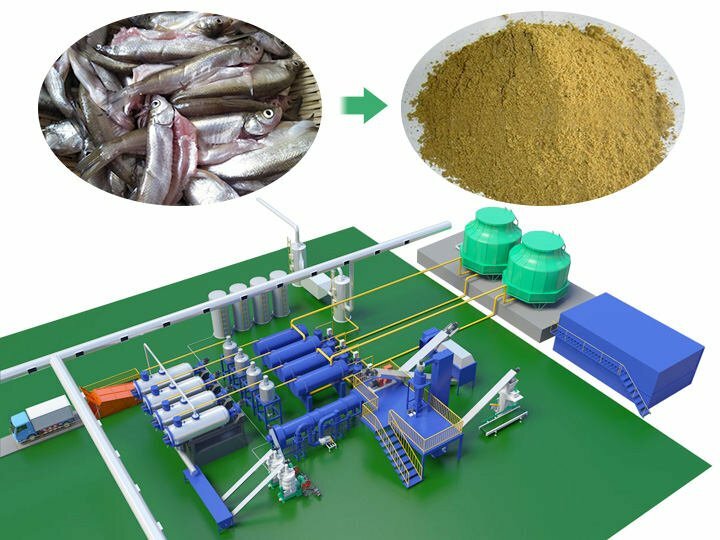

Shuliy line produksi ikan tepung adalah seperangkat peralatan yang khusus mengubah limbah ikan (seperti kepala ikan, tulang ikan, isi ikan, dll.) atau ikan segar menjadi ikan tepung berprotein tinggi dan minyak ikan. Kapasitasnya 1-5 ton per hari, 10-50 ton per hari, 50-100 ton per hari, 100-250 ton per hari, dan bahkan lebih besar.

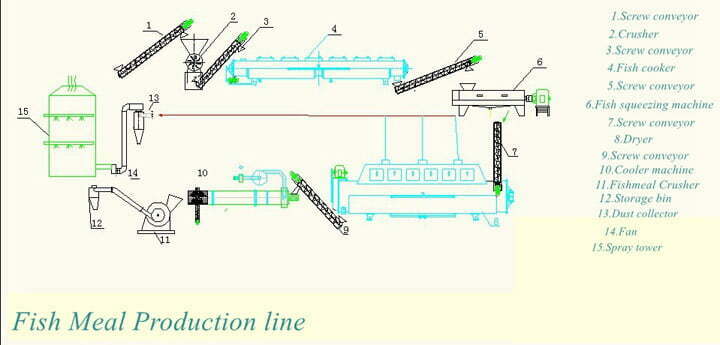

Pabrik pengolahan ikan tepung ini mencakup penggiling ikan, mesin memasak ikan, mesin press, pengering uap, mesin penyaring pendingin, mesin penggiling, dan mesin pengemas. Selama langkah press sekrup, minyak ikan diproduksi. Jika Anda menginginkan minyak ikan, diperlukan pemisah minyak ikan.

Ini banyak digunakan di pabrik pakan, peternakan akuakultur, pabrik daur ulang protein hewan, dan industri lain, dan memiliki tingkat pengembalian investasi yang tinggi serta efisiensi perlindungan lingkungan yang kuat. Tertarik? Silakan hubungi kami untuk informasi lebih lanjut!

Apa itu ikan tepung?

Ikan tepung adalah bubuk coklat kaya protein dan nutrisi, yang umum digunakan dalam produksi pakan hewan, seperti makanan kucing dan anjing, pakan kelinci, dan pakan unggas. Terbuat dari ikan yang tidak cocok untuk konsumsi manusia, ikan kecil, ikan mati atau residu proses ikan (misalnya kepala ikan, tulang ikan, isi, dll.) setelah dipotong, dikukus, diperas, dikeringkan, dan proses lainnya.

Karena nilai nutrisi yang tinggi dan permintaan pasar, produksi ikan tepung menjadi bisnis yang sangat menjanjikan dalam beberapa tahun terakhir.

Bagaimana cara membuat ikan tepung dengan lini produksi ikan tepung?

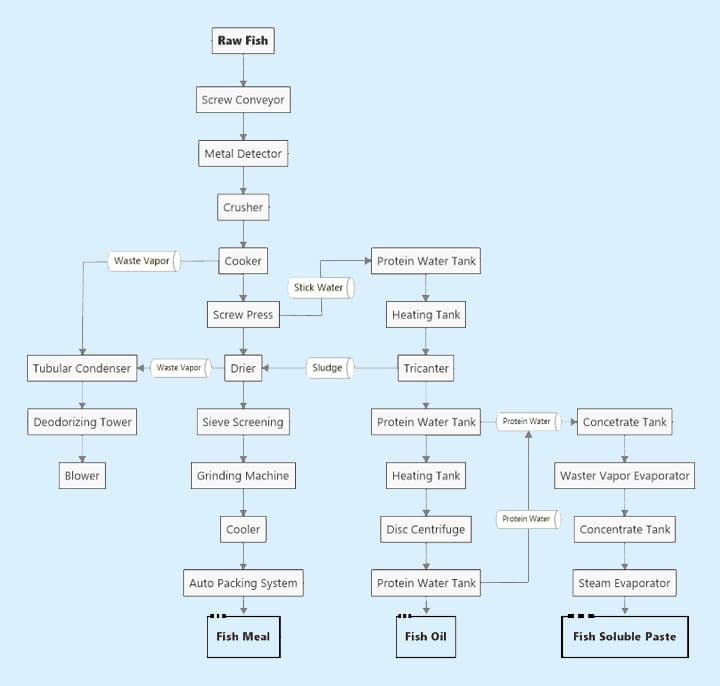

Prosedur pengolahan ikan tepung umum meliputi pemotongan ikan→pengolahan ikan→penekanan ikan matang→pengeringan uap→pendinginan dan penyaringan bubuk ikan→penggilingan ikan tepung→pengemasan ikan tepung. Selama proses penekanan ikan, minyak ikan dibuat. Perlukah pemisah minyak ikan?

Langkah satu: menghancurkan ikan

mesin penggiling ikan ini digunakan untuk memotong limbah ikan, ikan segar, udang, dan larva ulat, dll. menjadi ukuran kecil ≤5mm. Jika bahan baku Anda berukuran kecil, Anda dapat melewati langkah ini dengan mengangkutnya langsung ke mesin memasak ikan melalui konveyor sekrup.

- Kapasitas: 500-1000kg/jam

- Daya: 5,5 kW

- Spesifikasi: 1200X600X1000mm (panjang, lebar, dan tinggi)

- Berat: 300kg

- Cangkang mesin terbuat dari baja tahan karat dan pisau terbuat dari 40Cr.

- Bagian atas dilengkapi dengan corong pengumpul, terbuat dari SUS304.

Langkah dua: memasak ikan

mesin memasak ikan mengadopsi metode pemanasan uap, jadi harus dipadukan dengan boiler untuk menyediakan sumber uap. Boiler dapat dibeli atau dibangun sendiri oleh pelanggan. Langkah memasak ikan ini memiliki dua fungsi utama dalam pengolahan ikan tepung: memasak dan sterilisasi.

- Waktu memasak: 20 menit

- Suhu memasak: 150℃-160℃

- Silinder dalam terbuat dari baja karbon Q345 dengan ketebalan 10mm.

- Silinder luar terbuat dari pelat baja Q235 dengan ketebalan 8mm.

- Dilengkapi dengan sambungan putar bermerek dan selang stainless steel.

- Satu rangka dengan guardrail tambahan dan tangga panjat tersedia.

Langkah tiga: penekanan ikan matang

Potongan ikan matang kemudian diangkut ke mesin peras ikan untuk mengeluarkan air dan lemak ikan dengan cepat. Mesin press sekrup ini dapat memeras produk jus seperti minyak ikan dan air dari ikan secara maksimal, dan mengeluarkan daging ikan yang halus dan residu ikan dari saluran pembuangan slag.

- Produk akhir: ikan mentah dan basah & campuran air minyak yang diekstraksi

- Diameter bilah sekrup 18mm, ketebalan bilah spiral 12mm, bahan 16MnR.

- Penutup luar dan tangki penerima bawah terbuat dari pelat baja tahan karat 304.

- Peralatan cocok opsional: pemisah minyak ikan

Langkah empat: pengeringan bubuk ikan

Setelah ditekan, residu ikan masih memiliki kandungan air tertentu. Oleh karena itu, kita harus menggunakan mesin pengering ikan tepung untuk pengeringan cepat. Mesin pengering putar ini dapat mengeringkan ikan tepung dengan cepat selama proses rotasinya dengan sumber panas uap boiler. Mesin pengering ini memiliki struktur tertutup penuh dan dilengkapi dengan penangkap debu, yang tidak akan menghasilkan pencemaran debu.

- Metode pengeringan: pengeringan uap

- Bahan silinder luar terbuat dari baja karbon Q235, ketebalan disesuaikan dengan kapasitas lini produksi ikan tepung secara keseluruhan.

- Peralatan ini berbentuk pelapis luar.

- Bahan isolasi termal adalah alumina silikat, dan papan isolasi terbuat dari SUS304.

Langkah lima: penyaringan dan penggilingan ulang ikan tepung

Selama proses pembuatan ikan tepung, setelah pengeringan, ikan tepung harus disaring dengan mesin penyaring drum untuk mendapatkan bubuk ikan berukuran seragam. Mesin penyaring drum ini dapat diganti dengan berbagai jaring saring dengan lubang saring berbeda.

- Fungsi: pendinginan dan penyaringan, dibuang dalam dua tingkat

- Jaring baja tahan karat, ukuran: 5mmX5mm

- Penyangga terbuat dari Q235B, dan badan utama terbuat dari SUS304, δ=2mm.

Setelah penyaringan, bubuk ikan halus dapat dikemas, dan bubuk ikan yang tidak sesuai ukuran (biasanya 3 mm) dapat dihancurkan lagi dengan mesin penghancur kecil dengan penangkap debu untuk memastikan lingkungan yang tidak tercemar.

- Kapasitas: 600-800kg/jam (9FQ40-28)

- Ukuran penggilingan sesuai standar ikan tepung nasional

- Terbuat dari baja alat T12 dengan ketahanan aus yang baik

Langkah enam: pengemasan ikan tepung

Ikan tepung akhir dapat dikemas secara manual atau dikemas ke dalam paket kecil otomatis dengan mesin pengemasan otomatis. Kami dapat menyediakan mesin pengemasan khusus untuk pengemasan kuantitatif ikan tepung yang efisien tinggi dengan logo, huruf, merek, gambar yang disesuaikan.

- Model: TZ-DGS-50F

- Bahan aplikasi: Bubuk, bahan campuran

- Rentang pengisian: 5-50kg

- Presisi: ±0,2-0,5%

- Kecepatan pengemasan: 3-8 kantong/menit

- Tekanan udara/penggunaan gas: 0,4-0,6 MPa/ 1 m3/jam

- Daya: 380V/2,6KW

- Dimensi: 3000×1500×2500 mm

Keunggulan utama dari lini produksi ikan tepung Shuliy

- Berbagai kapasitas produksi

- Mesin ikan tepung kami memiliki dengan output 1-5 ton per hari, 10-50 ton per hari, 50-100 ton per hari atau lebih. Kami dapat menyesuaikan berbagai lini produksi ikan tepung berdasarkan kebutuhan nyata pelanggan kami.

- Bahan baja tahan karat SUS 304 berkualitas

- Semua peralatan di pabrik ikan tepung Shuliy menggunakan Bahan baja tahan karat SUS 304, yang tahan terhadap korosi dan tahan lama. Dengan demikian, mesin dapat digunakan dalam waktu yang lama.

- Ikan tepung dan minyak ikan berkualitas tinggi untuk pendapatan tinggi

- Penggunaan pabrik pengolahan ikan tepung Shuliy memastikan bahwa kandungan protein ikan tepung hingga 60% atau lebih, mengandung protein tinggi, lebih sedikit kotoran, mudah diserap, dan harga pasar lebih tinggi.

- Minyak ikan murni yang diekstraksi dapat digunakan di bidang kosmetik, farmasi, dan produk perawatan kesehatan, mewujudkan nilai maksimum dari bahan baku dan meningkatkan profitabilitas pelanggan.

- Program pengolahan perlindungan lingkungan

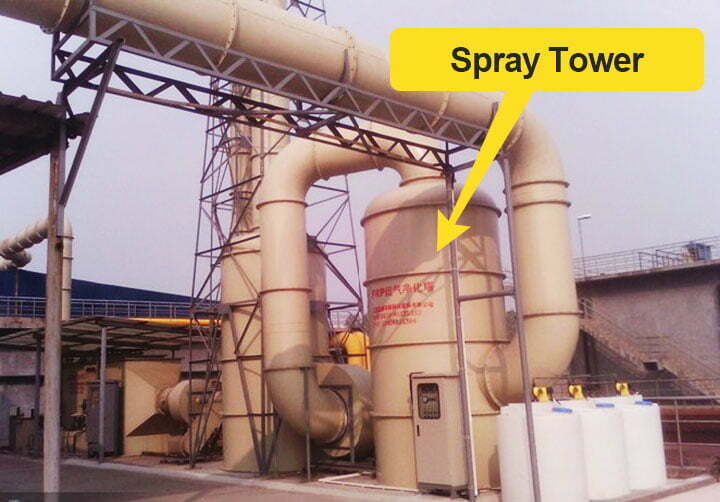

- Kami menyediakan siklon (penangkap debu), peralatan deodorisasi (menara semprot, kondensor) untuk membantu pelanggan merespons ulasan lingkungan dengan mudah dan mematuhi standar emisi lokal.

- Kustomisasi dan dukungan layanan

- Shuliy dapat menyediakan solusi kustom satu atap untuk lini produksi ikan tepung sesuai bahan baku, lokasi, anggaran, dll.

- Selain itu, kami menyediakan instalasi dan komisioning, pelatihan teknis, dan layanan purna jual jarak jauh untuk memastikan operasi peralatan yang panjang dan stabil.

Aplikasi dari lini produksi ikan tepung

- Untuk membuat pakan ternak. Ikan tepung dapat digunakan untuk pengolahan pakan ternak. Utamanya digunakan untuk produksi pakan untuk hewan seperti babi, ayam, dan sapi. Pakan untuk hewan ini harus mengandung protein berkualitas tinggi, terutama untuk babi dan ayam muda. Karena hewan muda sedang dalam masa pertumbuhan yang pesat, permintaan akan protein dan proporsi asam amino dalam protein cukup tinggi. Ikan tepung adalah protein hewan yang proporsi asam amino-nya paling dekat dengan asam amino yang dibutuhkan hewan.

- Pakan untuk hewan akuatik. Bubuk ikan digunakan sebagai bahan baku utama untuk protein pakan seperti ikan, kepiting, dan udang dalam hewan akuatik. Rasio asam amino yang dibutuhkan untuk ikan tepung dan hewan akuatik paling dekat. Menambahkan ikan tepung dapat memastikan pertumbuhan hewan akuatik lebih cepat.

- Digunakan untuk membuat pakan hewan bulu. Bubuk ikan dapat digunakan untuk membuat pakan untuk beberapa hewan bulu seperti rubah dan jangkrik. Hewan bulu sebagian besar karnivora, dan permintaan akan protein meningkat pesat. Ikan tepung berkualitas tinggi sebagai bahan baku protein adalah pilihan utama untuk bahan pakan hewan ini.

Uji operasional mesin ikan tepung

Pabrik ikan tepung dapat mengeringkan bahan bubuk dan granul dengan kebutuhan khusus. Untuk mencapai kondisi yang baik, diperlukan percobaan operasi uji dari mesin ikan tepung.

Persyaratan khusus adalah sebagai berikut:

- Nyalakan motor utama dan pastikan pengarah utama berputar dengan benar.

- Amati apakah rotasi pengarah utama dan komponen transmisi berfungsi lancar, periksa apakah inlet dan outlet uap terhubung ke peralatan pengering, dan apakah manometer berada dalam rentang tekanan kerja.

- Nyalakan motor, dan pengarah utama beroperasi dengan lancar. Setelah suhu naik, sesuaikan kecepatan motor dan film merata di roller untuk mengontrol kadar air bahan.

- Nyalakan motor, keluarkan bahan kering yang selesai dikeringkan, dan sesuaikan kecepatan motor sesuai jumlah pengeringan yang selesai.

Setelah menyelesaikan langkah uji coba di atas dari pabrik ikan tepung, jika tidak ada fenomena abnormal, Anda dapat memulai penggunaan resmi.

Peralatan yang cocok digunakan dalam lini produksi ikan tepung

Konveyor sekrup dalam pabrik ikan tepung

Pabrik pengolahan ikan tepung kami memiliki screw conveyor khusus, dengan struktur sederhana dan biaya rendah. Ini adalah konveyor yang umum digunakan dalam industri. Konveyor ikan tepung ini andal, mudah dipelihara, dan memakan ruang kecil.

Oleh karena itu, dapat meningkatkan efisiensi produksi bubuk ikan dan menghemat banyak biaya tenaga kerja.

Dalam produksi industri, tidak dapat dihindari menghasilkan gas buang, asap, dan debu industri. Jika polutan ini langsung dibuang ke atmosfer, tidak hanya akan mencemari udara tetapi juga membahayakan kesehatan manusia.

Untuk mencegah masalah di atas, kami dilengkapi unit pemurnian udara khusus di pabrik pengolahan ikan tepung, yaitu menara semprot. Menara semprot juga dikenal sebagai peralatan deodorisasi semprot, menara pemurnian semprot, atau scrubber semprot. Ini dapat secara efektif mengumpulkan debu dan gas berbahaya melalui beberapa filter. Kinerja inovatif dan canggih dari peralatan ikan tepung

Inovasi dan kinerja canggih dari pabrik ikan tepung

- Kami menggunakan ekstraksi udara panas alih-alih uap tidak langsung sebagai sumber panas kering, dan efisiensi pemanasan akan meningkat secara signifikan. Diperkirakan konsumsi energi akan menghemat lebih dari 30% dibandingkan peralatan proses asli.

- Teknologi pengeringan cepat suhu rendah dapat melindungi asam amino dalam ikan tepung dari kerusakan secara efektif. Ini mengurangi tingkat kehilangan protein sejati dalam ikan tepung dari 15-30% menjadi kurang dari 5%, mencapai atau melebihi standar ikan tepung yang sama.

- Desain kami dipertahankan dalam kondisi tekanan negatif tertutup, dengan produksi otomatis berkelanjutan, efisiensi tinggi, konsumsi energi rendah, tanpa pencemaran lingkungan.

Mesin pembuatan ikan tepung 500kg/jam mulai beroperasi di Libya

Ikan tepung memiliki kandungan protein tinggi dan terutama digunakan dalam pakan hewan. Karena nilai ekonominya yang sangat tinggi, banyak negara mulai mendirikan pabrik pengolahan ikan tepung untuk memproduksi berbagai ikan tepung berkualitas tinggi secara besar-besaran.

Baru-baru ini, seorang pelanggan Libya memesan dari kami. Pabriknya terletak di tepi laut dan bahan baku utamanya adalah ikan putih.