To produce high-quality defatted fishmeal, It is indispensable to equip a professional fish meal production line. The fish meal made by the Shuliy fishmeal processing plant is screened through layers, separated, and finally beaten to the effect of defatting. Our 10t/20h defatted fish meal production machine mainly consists of fish crusher, fish cooker, screw press, fish meal dryer, and corresponding auxiliary equipment. With this set of equipment, we can save a lot of time, labor costs and make the high-quality fish meal that our customers need.

What is defatted fish meal?

There are semi-defatted fish meal and full-defatted fish meal. Our fish meal product is characterized by a very low-fat content. The production process of defatted fishmeal is to process raw fish through a series of processes such as fish cooling, fish cutting, fish cooking, fish squeezing, fish drying, fish meal screening, fish meal crushing. The fish meal produced by our Shuli fish meal equipment is defatted. And finally, the water, oil, and fish meal are separated out.

Superiorities of fish meal

The rich nutrition and excellent digestibility of fishmeal have made it widely used in the feed industry, especially in feed for young animals. The content of essential amino acids in fishmeal protein is quite high, especially the methionine, cysteine, lysine, threonine, and tryptophan content. And animals are able to use the amino acids in the form of natural peptides in fishmeal, which is very effective in improving the overall balance of essential amino acids in bait.

The raw material of fish meal machine.

The main raw material of this 10t/20h defatted fish meal machine is fresh fish. It can process 10T of fresh fish in one day, and the final amount of defatted fish meal processed is 2400kg. The content of water in the finished product is less than 10%.

Process flow of fish meal

- Frozen fresh fish.

- Use the fish crusher to cut the frozen fresh fish.

- Cook the fish through fish cooking machine.

- Use the screw press to squeez the fish.

- Separate the fish meal, water and fish oil through horizontal centrifuge.

- The fish meal dryer dries the wet fishmeal extruded from the fish screw press and reduces the water content of the fish meal to less than 10%.

- Sieve out fish meal with fish meal screening machine, and the remaining material will be further crushed and processed into fish meal.

Equipment specifications of fish meal machine

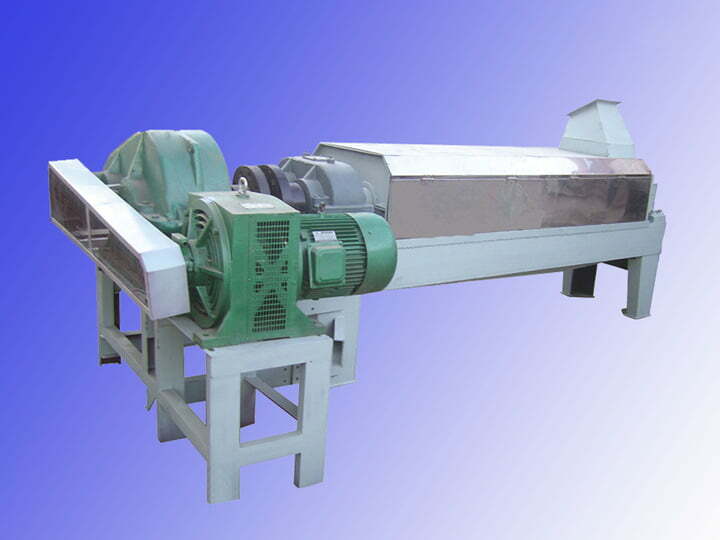

The whole set of 10t/20h defatted fish meal machine production line includes screw conveyor, cooking machine, press machine, dryer, electrical control cabinet, oil and water separation cylinder, gear pump, crusher, pulverizer, spray tower, rotary cooling brush. The total power used for the whole set of equipment is 109kw.

| main equipment | specification | QTY | POWER KW |

fish crusher | 1 | 5.5 | |

fish cooker | φ530×5000 The outer insulation is made of stainless steel 430, thickness 0.7mm. The inner and outer barrel of the equipment is made of Q235B carbon steel. | 1 | 3 |

screw press | φ325×1600 The outer cover is made of stainless steel 304, thickness 1.2mm. The equipment screen is made of 304 stainless steel. | 1 | 4 |

fish meal dryer | φ1000×5000 Inside configuration of stirring teeth. The inner and outer barrel of the equipment is made of Q235B carbon steel. Outer insulation made of stainless steel 430, thickness 0.7mm. V=30rpm. | 1 | 7.5 |

screw conveyor | φ200×5000 Cycloidal needle reducer material is SUS304 stainless steel | 2 | 1.5 |

electrical control cabinet | 1 | ||

oil and water separation cylinder | φ1000×2000 The cylinder body is made of carbon steel | 2 | |

gear pump | 1 | 1.5 | |

fish meal crusher | 1 | 7.5 | |

spray tower | φ1500×3500 | 1 | |

rotary cooling brush | φ1000×2500 | 1 | 2.2 |

The above parameters are for reference only. If you want to know the detailed parameters of a machine or have any questions about the 10T/20H defatted fish meal machine, welcome to consult our customer service or leave your personal information on the website. We will be the first time to get in touch with you and solve your problems.

10T/D fish meal plant was exported to Morocco

In May 2018, a customer from Morocco ordered a 10T/D fish meal production line from our fish meal machine factory. This is the second time for him to cooperate with us. The reason why the customer chose to work with us again was that: Firstly, he thought we were a reliable fishmeal machine supplier based on his first cooperation experience. Secondly, the rising price of fishmeal and the increasing market demand prompted him to expand his fishmeal production scale.

Note:

- Customers can choose to increase or decrease the above fish meal processing equipment according to the actual local situation.

- If Customers need to install the fish meal equipment, the installation cost need to be charged separately.

- The above motors are quoted as AC380V, 50HZ, if you want to change the voltage and frequency, you need to charge separately.

- All the equipment needs to be equipped with an 8-ton steam boiler whose working steam is 1.0MPa. Customers need to purchase this machine by themselves.

- The above prices are ex-factory prices including VAT.