La línea de producción de harina de pescado de Shuliy es un conjunto de equipos especializados en convertir residuos de pescado (como cabeza, espina, vísceras, etc.) o pescado fresco en harina de pescado de alta proteína y aceite de pescado. Su capacidad tiene 1-5t por día, 10-50t por día, 50-100t por día, 100-250t por día e incluso mayor.

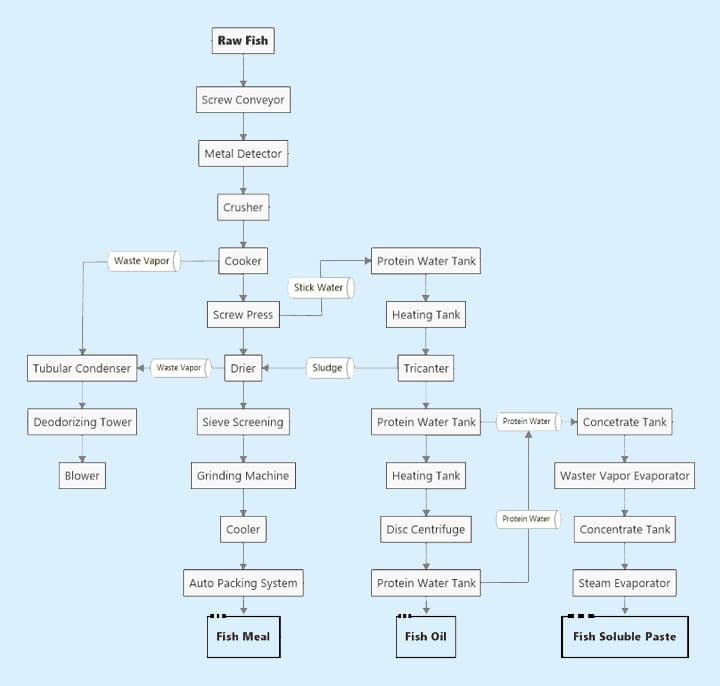

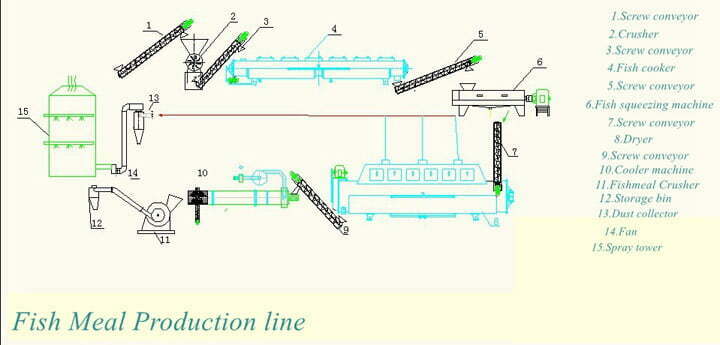

Esta planta de procesamiento de harina de pescado incluye la máquina de trituración de pescado, cocedor de pescado, prensa de tornillo, secador de vapor, máquina de tamizado de enfriamiento, máquina de molienda y máquina de envasado. Durante el paso de la prensa de tornillo, se produce el aceite de pescado. Si necesita aceite de pescado, se requiere un separador de aceite de pescado.

Se utiliza ampliamente en plantas de procesamiento de alimentos, granjas acuícolas, plantas de reciclaje de proteínas animales y otras industrias, y se caracteriza por alto retorno de inversión y fuerte eficiencia en protección ambiental. ¿Interesado? ¡Contáctenos para más información!

¿Qué es la harina de pescado?

La harina de pescado es un polvo marrón rico en proteínas y nutrientes, que se usa comúnmente en la producción de alimentos para animales, como comida para gatos y perros, comida para conejos y alimento para aves. Se fabrica principalmente a partir de algunos peces no aptos para consumo humano, peces pequeños, peces muertos o residuos de procesamiento de pescado (por ejemplo, cabeza, espinas, vísceras, etc.) después de cortar, vaporizar, prensar, secar y otros procesos.

Debido al alto valor nutricional y la demanda del mercado, la producción de harina de pescado se ha convertido en un negocio muy prometedor en los últimos años.

¿Cómo hacer harina de pescado con la línea de producción de harina de pescado?

El procedimiento común de procesamiento de harina de pescado incluye corte de pescado→cocción de pescado→prensado de pescado cocido→secado al vapor→enfriamiento y tamizado de polvo de pescado→molienda de harina de pescado→embalaje de harina de pescado. Durante el prensado de pescado, se produce el aceite de pescado. Verifique si necesita un separador de aceite de pescado.

Paso uno: trituración de pescado

Esta máquina de trituración de pescado se usa para cortar residuos de pescado, pescado fresco, camarones y gusanos de harina, etc., en tamaños pequeños de ≤5 mm. Si sus materias primas son de tamaño pequeño, puede omitir este paso transportándolas directamente al cocedor de pescado mediante el transportador de tornillo.

- Capacidad: 500-1000kg/h

- Potencia: 5.5 kW

- Especificación: 1200X600X1000mm (longitud, ancho y alto)

- Peso: 300kg

- La carcasa de la máquina está hecha de acero inoxidable y las cuchillas son de 40Cr.

- La parte superior está equipada con una tolva de recolección, hecha de acero inoxidable SUS304.

Paso dos: cocción de pescado

La máquina de cocción de pescado adopta el método de calefacción por vapor, por lo que debe coincidir con una caldera que proporcione la fuente de vapor. La caldera puede comprarse o construirse por los propios clientes. Este paso de cocción de pescado tiene dos funciones principales para procesar harina de pescado: cocción y esterilización.

- Tiempo de cocción: 20 minutos

- Temperatura de cocción: 150℃-160℃

- El cilindro interior está hecho de acero al carbono Q345 con un grosor de 10 mm.

- El cilindro exterior está hecho de placa de acero Q235 con un grosor de 8 mm.

- Está equipado con juntas giratorias de marca y mangueras de acero inoxidable.

- Soporte de una pieza con barandilla adicional y escalera de acceso.

Paso tres: exprimido de pescado cocido

Luego, los trozos de pescado cocido se transportan a la máquina de exprimido de pescado para extraer rápidamente el agua y la grasa del pescado. Esta máquina de prensa de tornillo puede exprimir al máximo los productos de jugo como aceite de pescado y agua del pescado, y descargar la carne de pescado finamente dividida y los residuos de pescado desde la salida de escoria.

- Productos finales: harina de pescado cruda y húmeda y mezcla de agua y aceite extraído

- El diámetro de la cuchilla de tornillo es de 18 mm, el grosor de la espiral es de 12 mm, material 16MnR.

- La cubierta exterior y el tanque receptor inferior están hechos de placa de acero inoxidable 304.

- Equipo opcional coincidente: separador de aceite de pescado

Paso cuatro: secado de polvo de pescado

Después de prensar, los residuos de pescado aún contienen cierta cantidad de agua. Por lo tanto, debemos usar la máquina de secado de harina de pescado para un secado rápido. Esta máquina secadora rotatoria puede secar la harina de pescado rápidamente durante su proceso de rotación con la fuente de calor de vapor de caldera. Esta máquina secadora tiene una estructura completamente cerrada y está equipada con un colector de polvo, lo que no producirá contaminación por polvo.

- Método de secado: secado al vapor

- El material del cilindro exterior es acero al carbono Q235, y el grosor coincide con la capacidad de toda la línea de producción de harina de pescado.

- El equipo tiene estructura de recubrimiento exterior.

- El material del aislamiento térmico es silicato de aluminio, y la placa de aislamiento es de acero inoxidable SUS304.

Paso cinco: tamizado y reprocesamiento de harina de pescado

Durante la línea de producción de harina de pescado, después del secado, la harina de pescado debe ser tamizada por una máquina de tamizado de tambor para obtener polvo de pescado de tamaño uniforme. La máquina de tamizado de tambor puede cambiarse con diferentes mallas de pantalla con diferentes orificios de tamizado.

- Funciones: enfriamiento y tamizado, descargados en dos niveles

- Malla de acero inoxidable, tamaño: 5mmX5mm

- El soporte está hecho de Q235B, y el cuerpo principal está hecho de SUS304, δ=2mm.

Después del tamizado, el polvo de pescado fino puede envasarse, y el polvo de pescado que no tenga el tamaño requerido (generalmente 3 mm) puede triturarse nuevamente con una pequeña máquina trituradora con colector de polvo para garantizar un entorno sin contaminación.

- Capacidad: 600-800 kg/h (9FQ40-28)

- Tamaño de molienda según la norma nacional de harina de pescado

- Hecho de acero de herramienta T12 con buena resistencia a la abrasión

Paso seis: envasado de harina de pescado

La harina de pescado final puede envasarse manualmente o envasarse en pequeños paquetes individuales mediante una máquina de envasado automática. Podemos proporcionar la máquina de envasado especial para un envasado cuantitativo altamente eficiente de productos de harina de pescado con el logotipo, letras, marcas, imágenes personalizadas, etc.

- Modelo: TZ-DGS-50F

- Materiales de aplicación: polvo, material mezclado

- Rango de llenado: 5-50kg

- Precisión: ±0.2-0.5%

- Velocidad de envasado: 3-8 bolsas/min

- Presión de aire / consumo de gas: 0.4-0.6 MPa / 1 m3/h

- Potencia: 380V/2.6KW

- Dimensiones: 3000×1500×2500 mm

Principales ventajas de la línea de producción de harina de pescado de Shuliy

- Varias capacidades de producción

- Nuestra máquina de harina de pescado tiene una producción de 1-5 toneladas por día, 10-50 toneladas por día, 50-100 toneladas por día o incluso más. Podemos personalizar diferentes líneas de producción de harina de pescado según los requisitos reales de nuestros clientes.

- Materiales de acero inoxidable SUS 304 de calidad

- Todos los equipos en la planta de harina de pescado de Shuliy adoptan Materiales de acero inoxidable SUS 304, que son resistentes a la corrosión y duraderos. Por lo tanto, la máquina puede usarse durante mucho tiempo.

- Harina de pescado y aceite de pescado de alta calidad para altos ingresos

- El uso de la planta de procesamiento de harina de pescado de Shuliy garantiza que el el contenido de proteína de la harina de pescado es de hasta el 60% o más, con alto contenido de proteínas, menos impurezas, fácil de absorber y con mayor precio de mercado.

- El aceite de pescado puro extraído puede ser utilizado en cosméticos, productos farmacéuticos y productos de cuidado de la salud, maximizando el valor de las materias primas y aumentando la rentabilidad de los clientes.

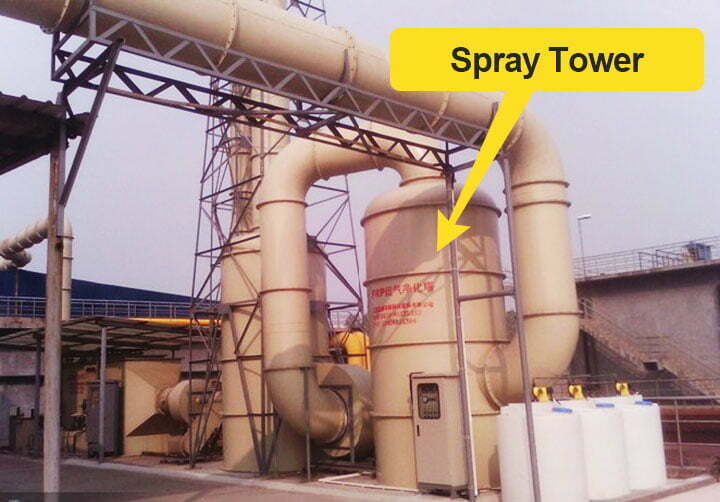

- Programa de tratamiento de protección ambiental

- Nosotros proporcionar ciclón (recogedor de polvo), equipo de desodorización (torre de pulverización, condensador) para ayudar a los clientes a responder fácilmente a la revisión ambiental y cumplir con las normas de emisión locales.

- Personalización y soporte de servicio

- Shuliy puede Proporcionar soluciones personalizadas de una sola parada para líneas de producción de harina de pescado según las materias primas, sitios, presupuestos, etc.

- Además, proporcionamos instalación y puesta en marcha, capacitación técnica y servicio postventa remoto para garantizar la operación a largo plazo y estable del equipo.

Aplicaciones de la línea de producción de harina de pescado

- Para hacer alimento para ganado. La harina de pescado puede usarse para el procesamiento de alimentos para animales. Se usa principalmente para la producción de alimentos para animales como cerdos, pollos y vacas. Estos alimentos deben contener proteínas de alta calidad, especialmente para cerdos jóvenes y pollos. Debido a que los animales jóvenes están en un período de crecimiento vigoroso, la demanda de proteínas y la proporción de aminoácidos en las proteínas son relativamente altas. La harina de pescado es una proteína animal en la que la proporción de aminoácidos es la más cercana a los aminoácidos requeridos por los animales.

- Alimento para animales acuáticos. La harina de pescado en polvo se usa como materia prima principal para proteínas en alimentos para peces, cangrejos y camarones en animales acuáticos. La proporción de aminoácidos requerida para la harina de pescado y los animales acuáticos es la más cercana. Agregar harina de pescado puede asegurar que los animales acuáticos crezcan más rápido.

- Utilizado para hacer alimento para animales peludos. La harina de pescado puede usarse para hacer alimento para algunos animales peludos como zorros y grillos. Los animales peludos son en su mayoría carnívoros, y la demanda de proteínas en crecimiento es grande. La harina de pescado de alta calidad como materia prima proteica es la primera opción para estos ingredientes de alimento animal.

Prueba de operación de la planta de harina de pescado

La planta de harina de pescado puede secar materiales en polvo y granulados con requisitos especiales. Para lograr una buena condición, se requiere un experimento de operación de prueba de la máquina de harina de pescado.

Los requisitos específicos son los siguientes:

- Iniciar el motor principal y asegurar que la dirección del rodillo principal sea correcta.

- Observe si la rotación del rodillo principal y los componentes de transmisión son flexibles, observe si la entrada y salida de vapor están conectadas al equipo de secado, y si el manómetro está dentro del rango de presión de trabajo.

- Iniciar el motor, y el rodillo principal funciona suavemente. Después de que la temperatura aumente, ajuste la velocidad del motor y la película uniforme en el rodillo para controlar el contenido de agua del material.

- Iniciar el motor, producir el material seco terminado y ajustar la velocidad del motor según la cantidad de secado terminada.

Después de completar los pasos de prueba anteriores de la planta de harina de pescado, si no hay fenómenos anormales, puede comenzar el uso formal.

Equipo coincidente utilizado en línea de producción de harina de pescado

Transportador de tornillo en planta de harina de pescado

Nuestra planta de procesamiento de harina de pescado tiene un transportador de tornillo especial, con estructura sencilla y bajo costo. Es un transportador comúnmente utilizado en la industria. El transportador de harina de pescado es confiable, fácil de mantener y ocupa un espacio reducido.

Por lo tanto, puede aumentar la eficiencia de producción de polvo de pescado y ahorrar mucho en costos laborales.

En la producción industrial, es inevitable producir algunos gases residuales, humo y polvo industrial. Si estos contaminantes se descargan directamente en la atmósfera, no solo contaminarán el aire sino que también dañarán la salud de las personas.

Para prevenir los problemas anteriores, equipamos una unidad de purificación de aire especial en la planta de harina de pescado, que es una torre de pulverización. La torre de pulverización también se conoce como equipo de desodoración por pulverización, torre de purificación por pulverización o depurador por pulverización. Puede recoger eficazmente polvo y gases nocivos mediante múltiples filtros. El rendimiento innovador y avanzado del equipo de harina de pescado

La innovación y el rendimiento avanzado de la planta de harina de pescado

- Utilizamos extracción de aire caliente en lugar del vapor indirecto original como fuente de calor seco, y la eficiencia de calefacción mejorará significativamente. Se espera que el consumo de energía ahorre más del 30% en comparación con el equipo de proceso original.

- La tecnología de secado rápido a baja temperatura y corto tiempo puede proteger eficazmente los aminoácidos en la harina de pescado de ser destruidos. Esto reduce la tasa de pérdida de proteína verdadera en la harina de pescado del 15-30% original a menos del 5%, alcanzando o superando el estándar de harina de pescado.

- Nuestro diseño se mantiene en estado de presión negativa cerrada, con producción automática continua, alta eficiencia, bajo consumo de energía, sin contaminación al medio ambiente.

Máquina de fabricación de harina de pescado de 500 kg/h puesta en producción en Libia

La harina de pescado tiene un alto contenido de proteínas y se usa principalmente en alimentación animal. Debido a su valor económico extremadamente alto, los inversores en muchos países han comenzado a establecer plantas de procesamiento de harina de pescado para producir una variedad de harina de pescado de alta calidad a gran escala.

Recientemente, un cliente libio realizó un pedido con nosotros. Su fábrica está ubicada junto al mar y la materia prima principal es pescado blanco.